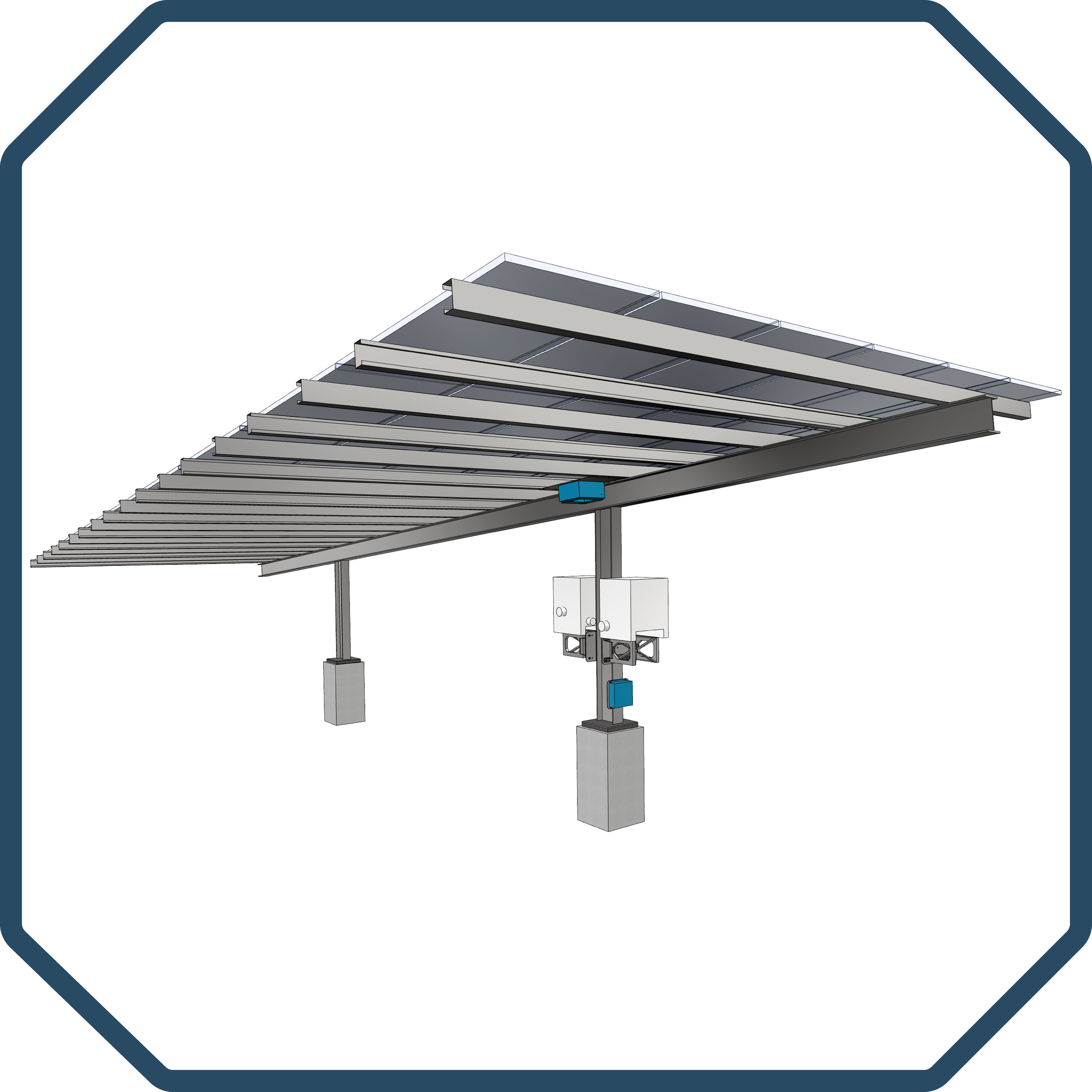

CARPORT INVERTER INSTALL SOLID MODEL

CARPORT INVERTER INSTALL DELIVERED

ABOUT THE CLIENT

Blue Ryzon offers professional services for solar contractors as well as turnkey installation solutions to their clients.

INTRODUCTION

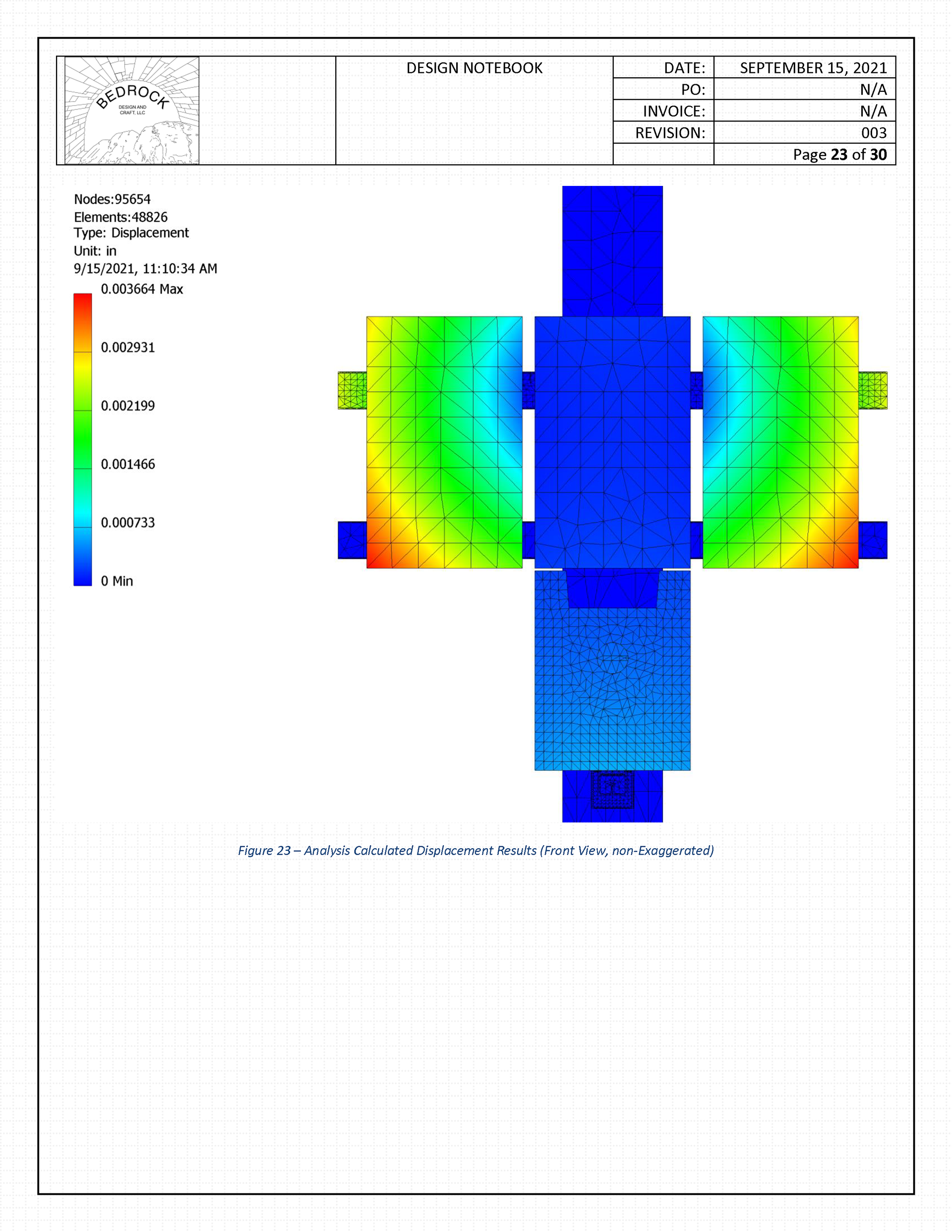

This project was brought to Bedrock by Blue Ryzon, a solar energy integrator who needed assistance with mounting inverters and junction boxes to a carport structure supporting solar panel arrays. This project required carefully assessing mechanical interface mounting details, component weights, defined assembly lifespan, and structural steel framing design (by others). The final design was reviewed and stamped by a professional engineer licensed in the state of California.

PROJECT SCOPE

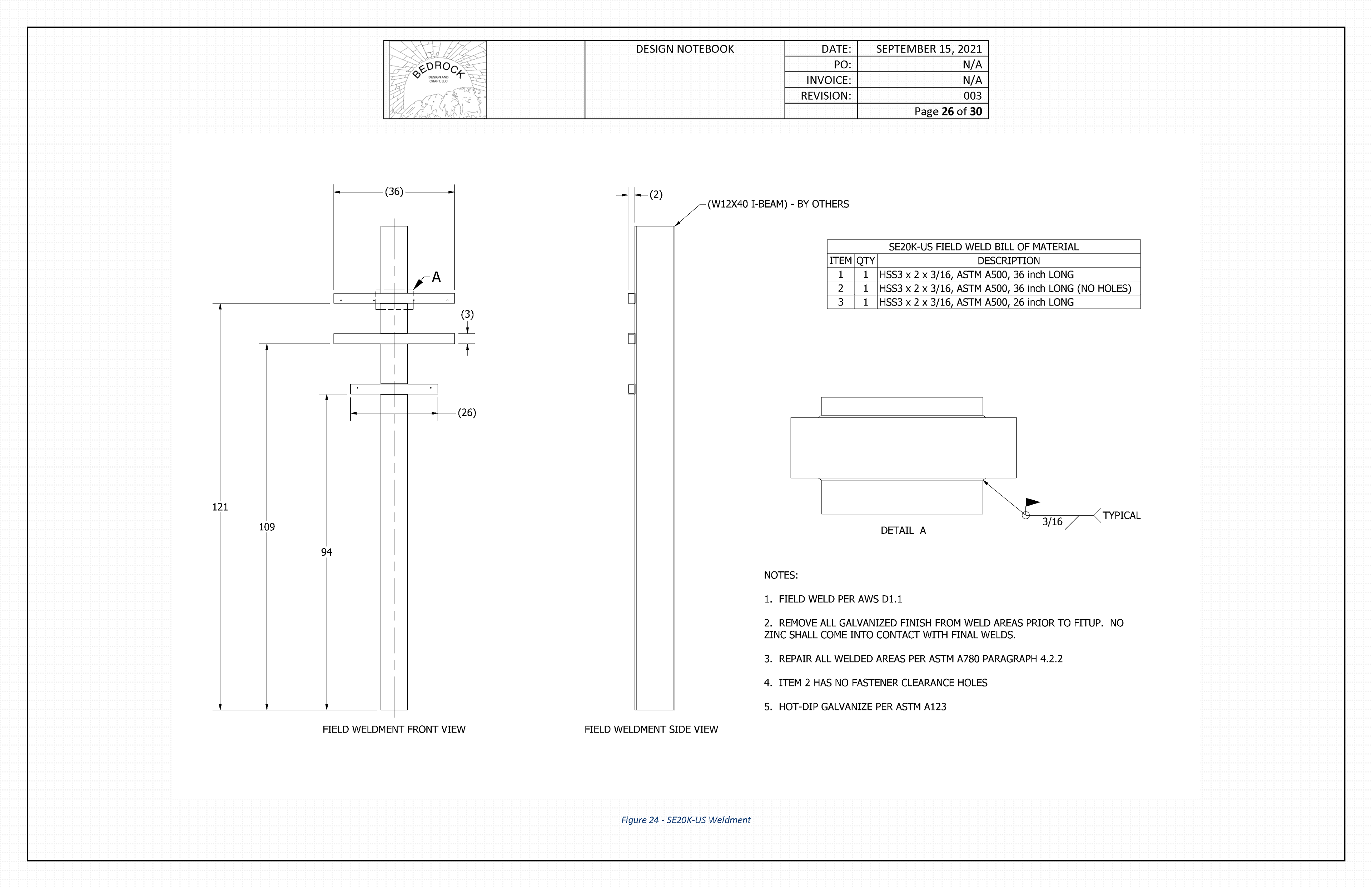

Bedrock Design and Craft, LLC produced solid models, a design notebook, and detail drawings of the final carport assembly. The stamped and sealed drawings were used to procure fabricated parts and drive the installation of the equipment in the field.

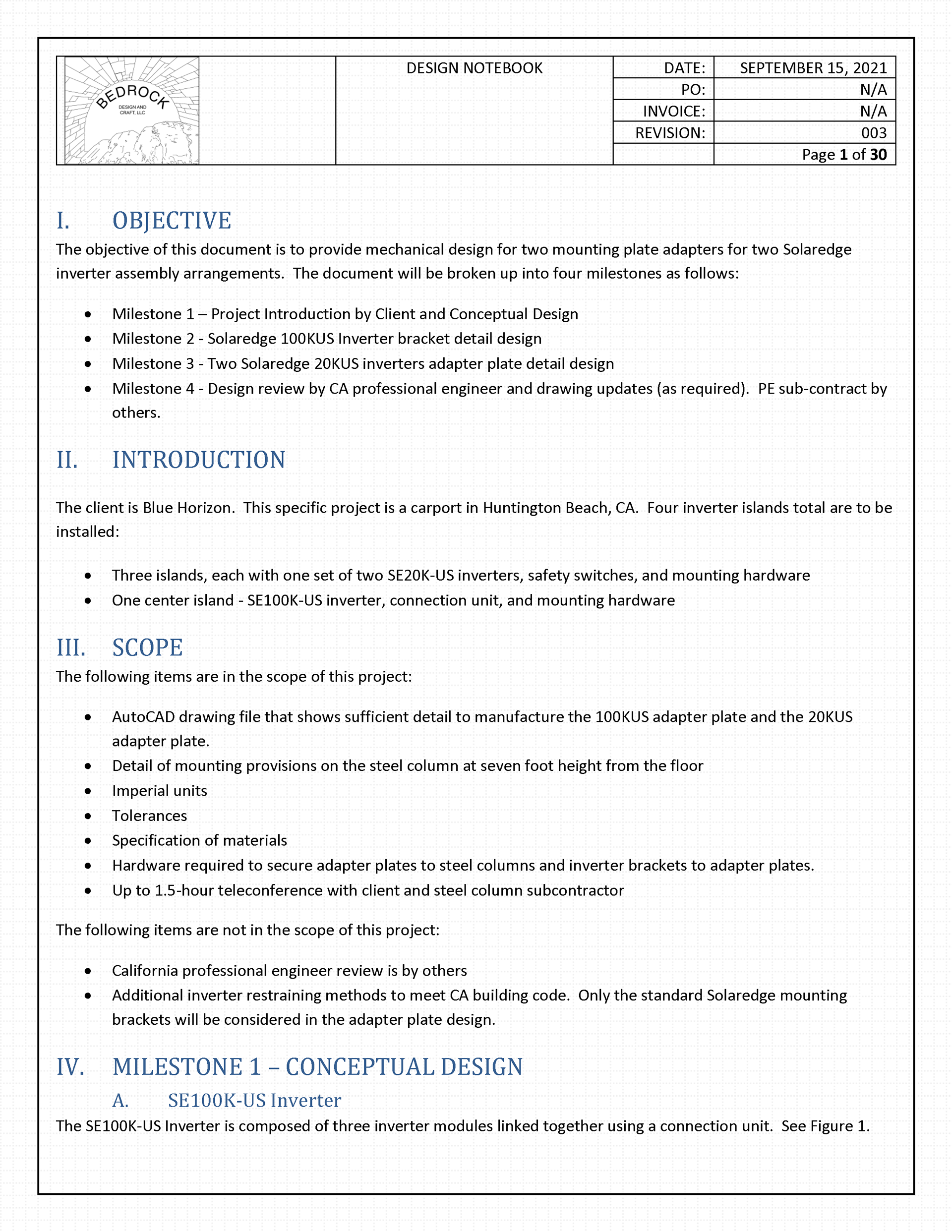

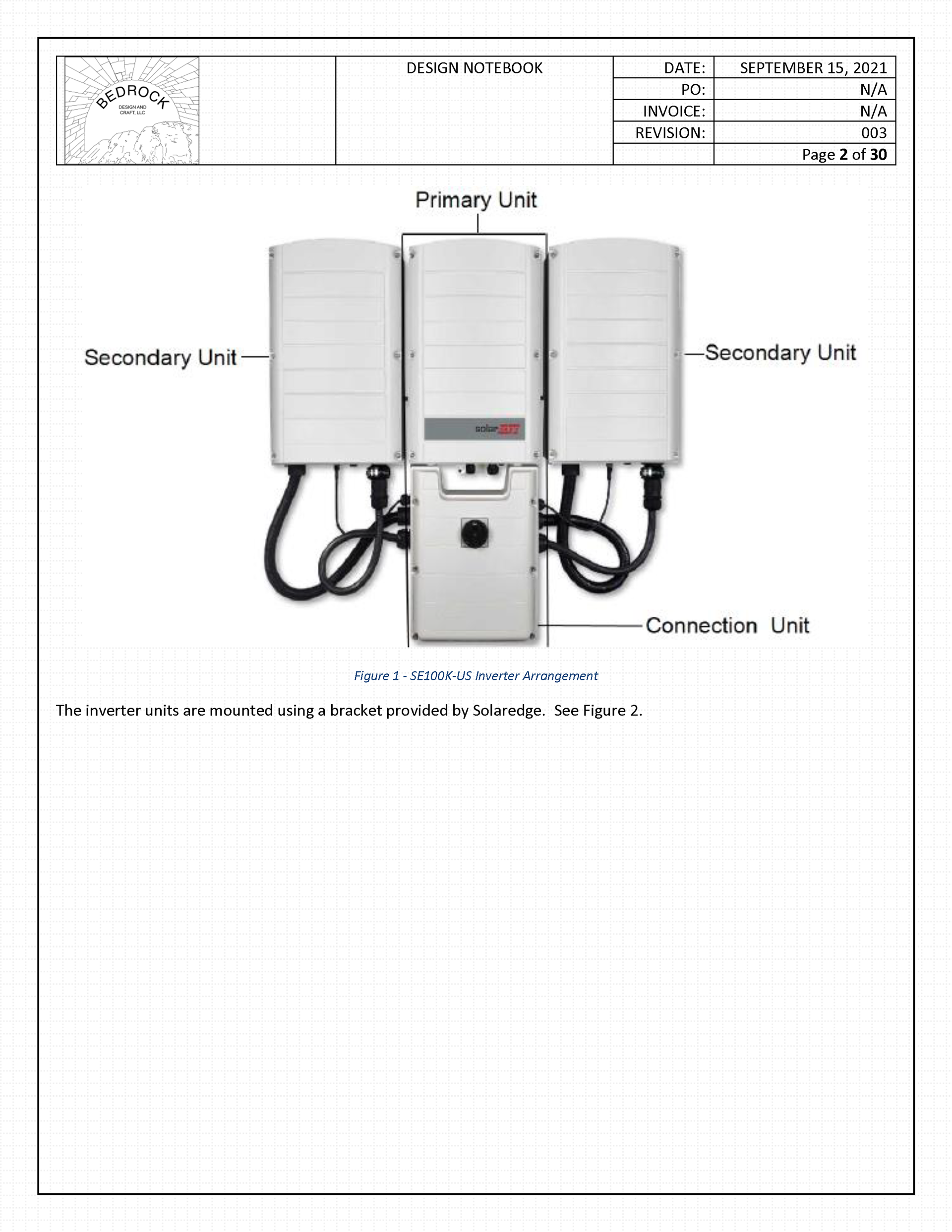

DESIGN NOTEBOOK

Bedrock produces formal design notebooks for clients. The notebooks capture all of the project details and justifications for design decisions made during the life of the project. The notebooks define the deliverables for the project and show exactly how the deliverables are met.

The design notebook below was produced as part of the partial design review milestone for this project.

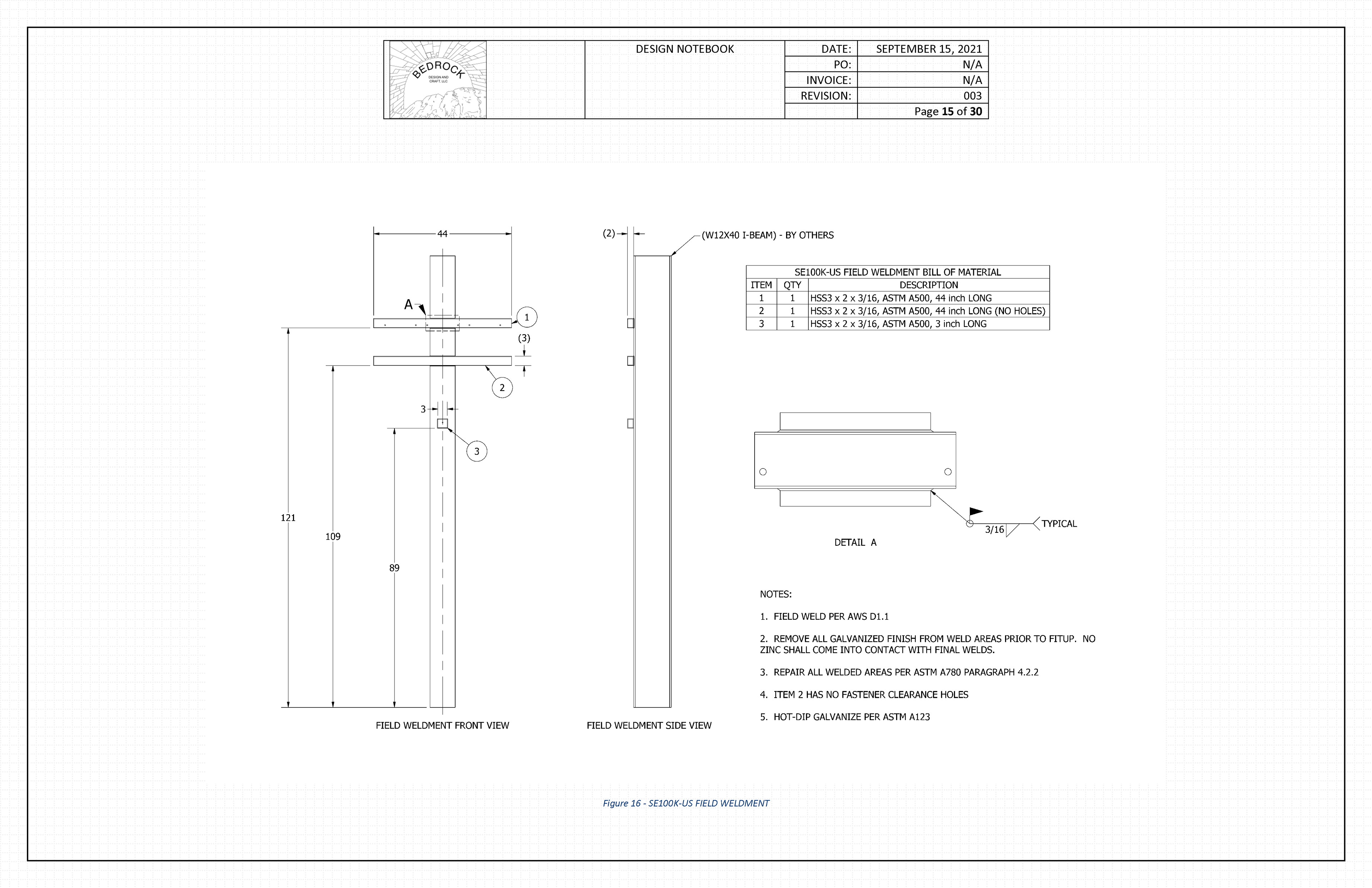

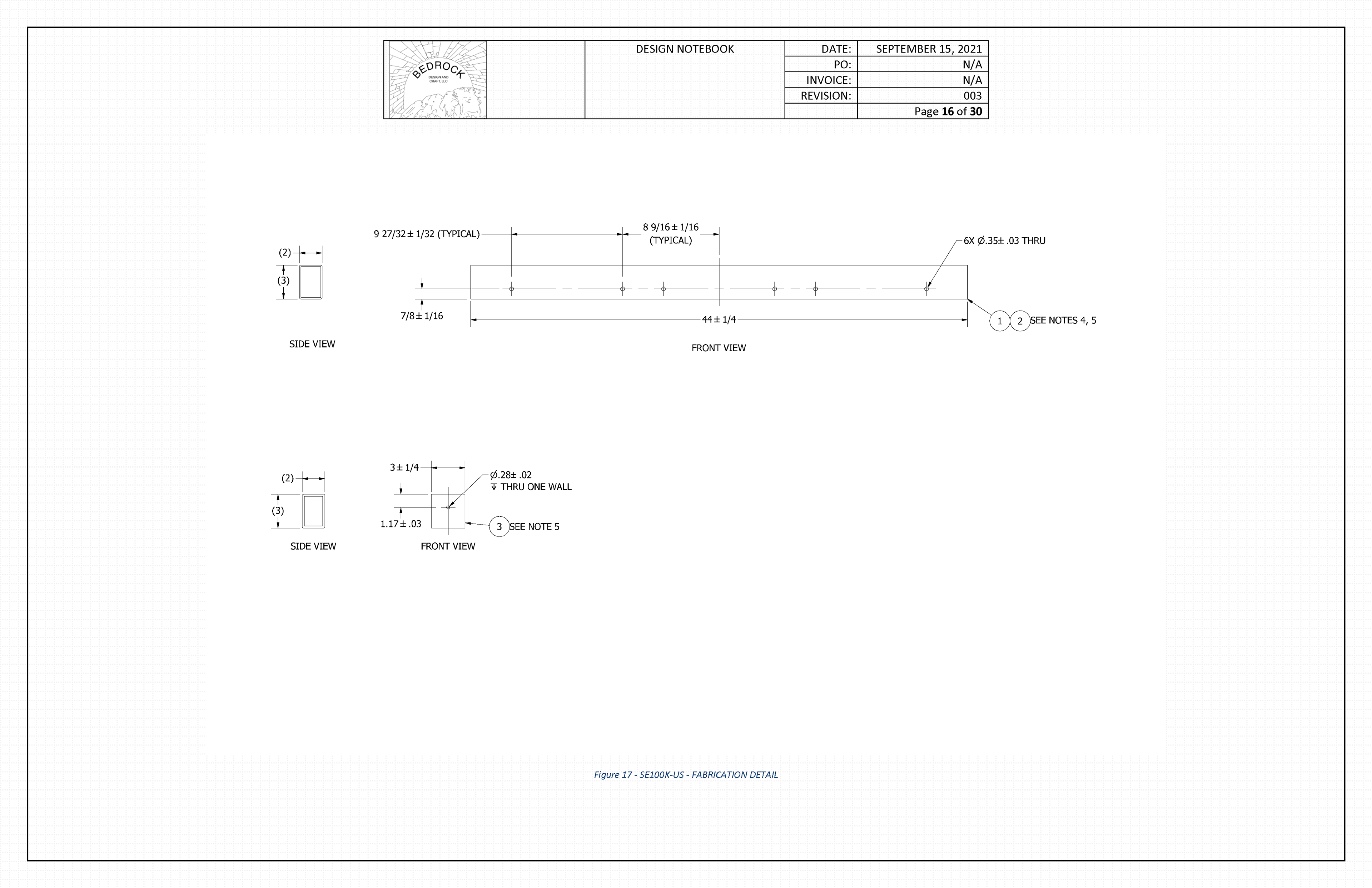

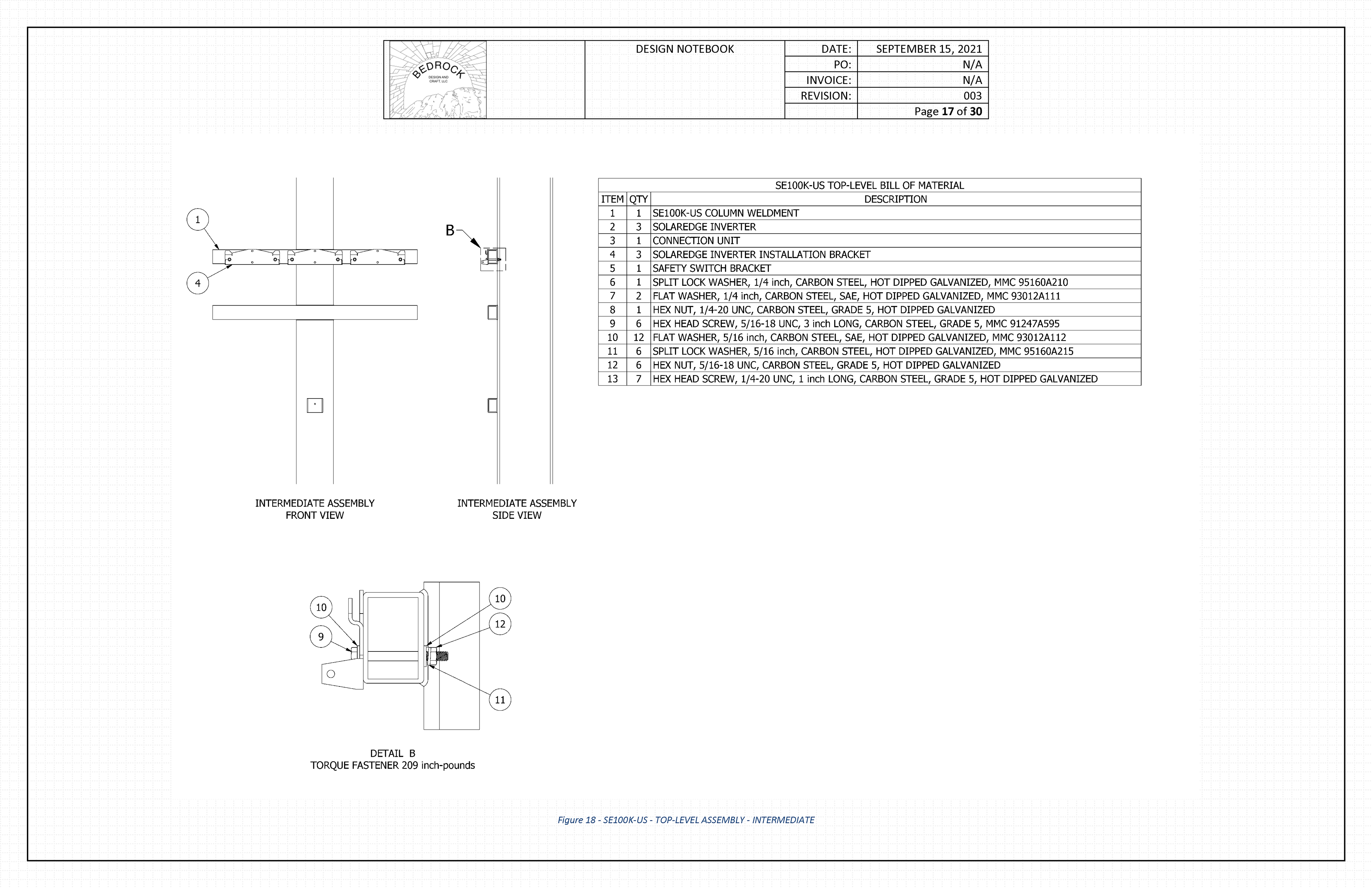

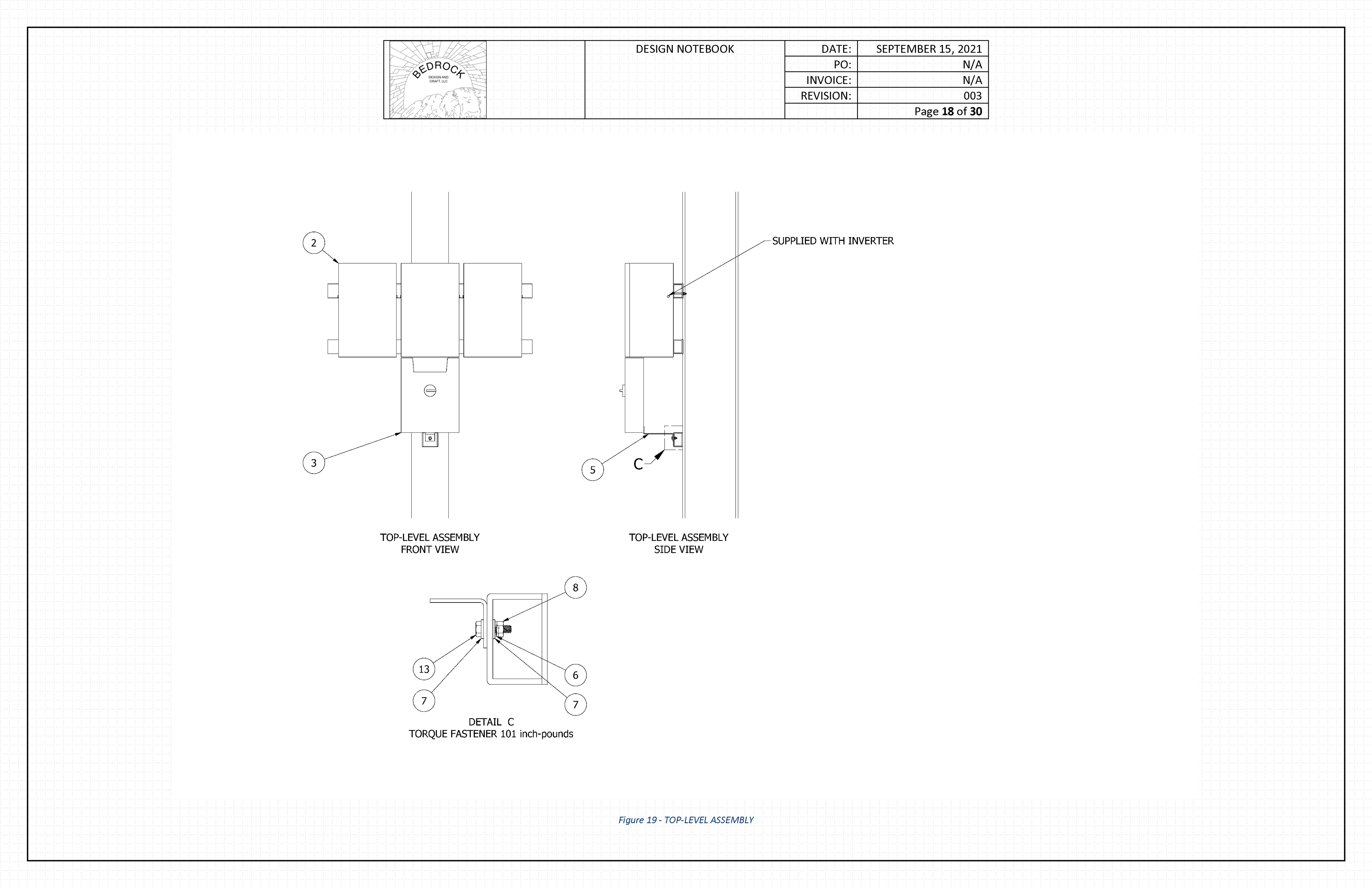

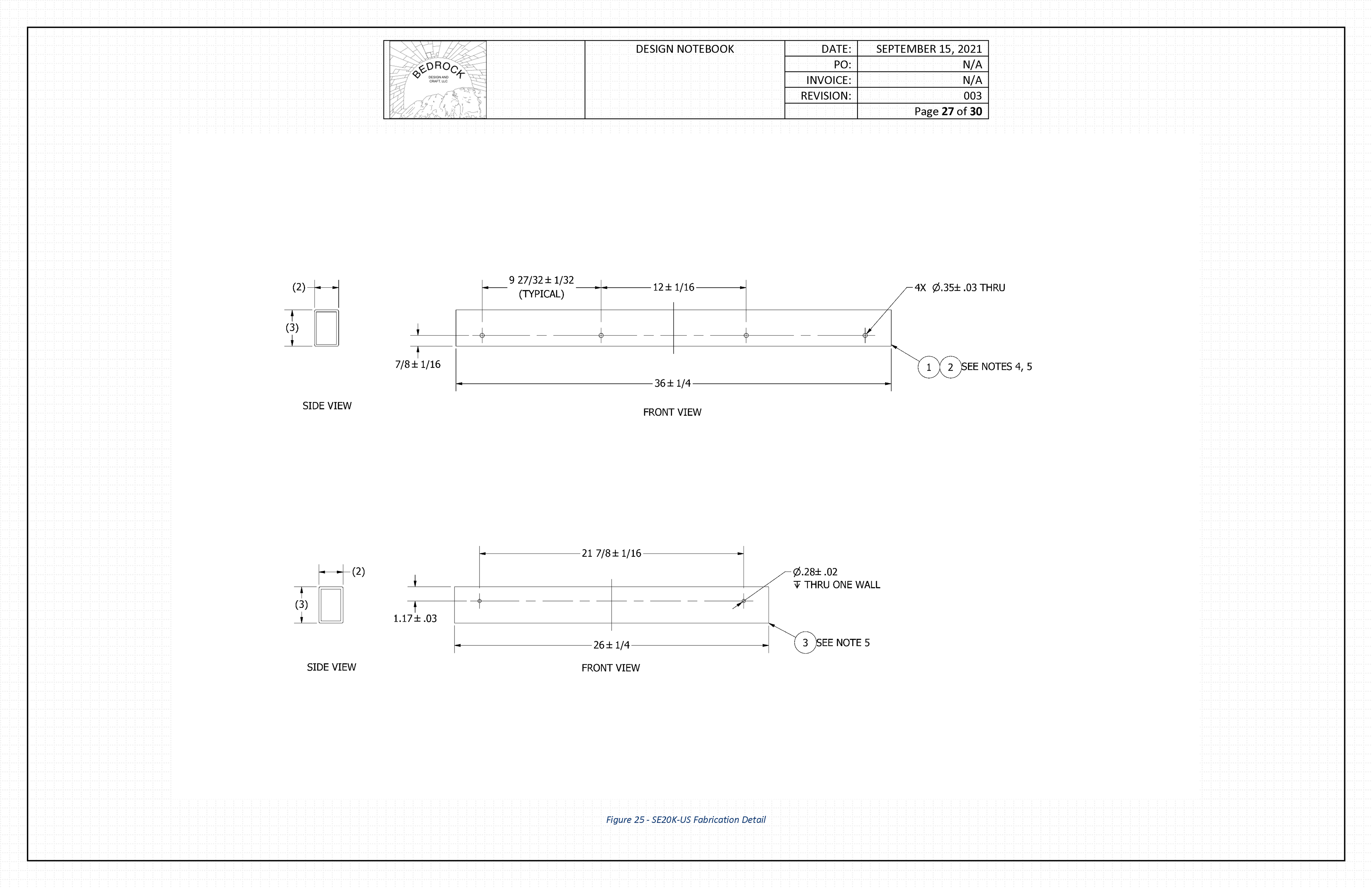

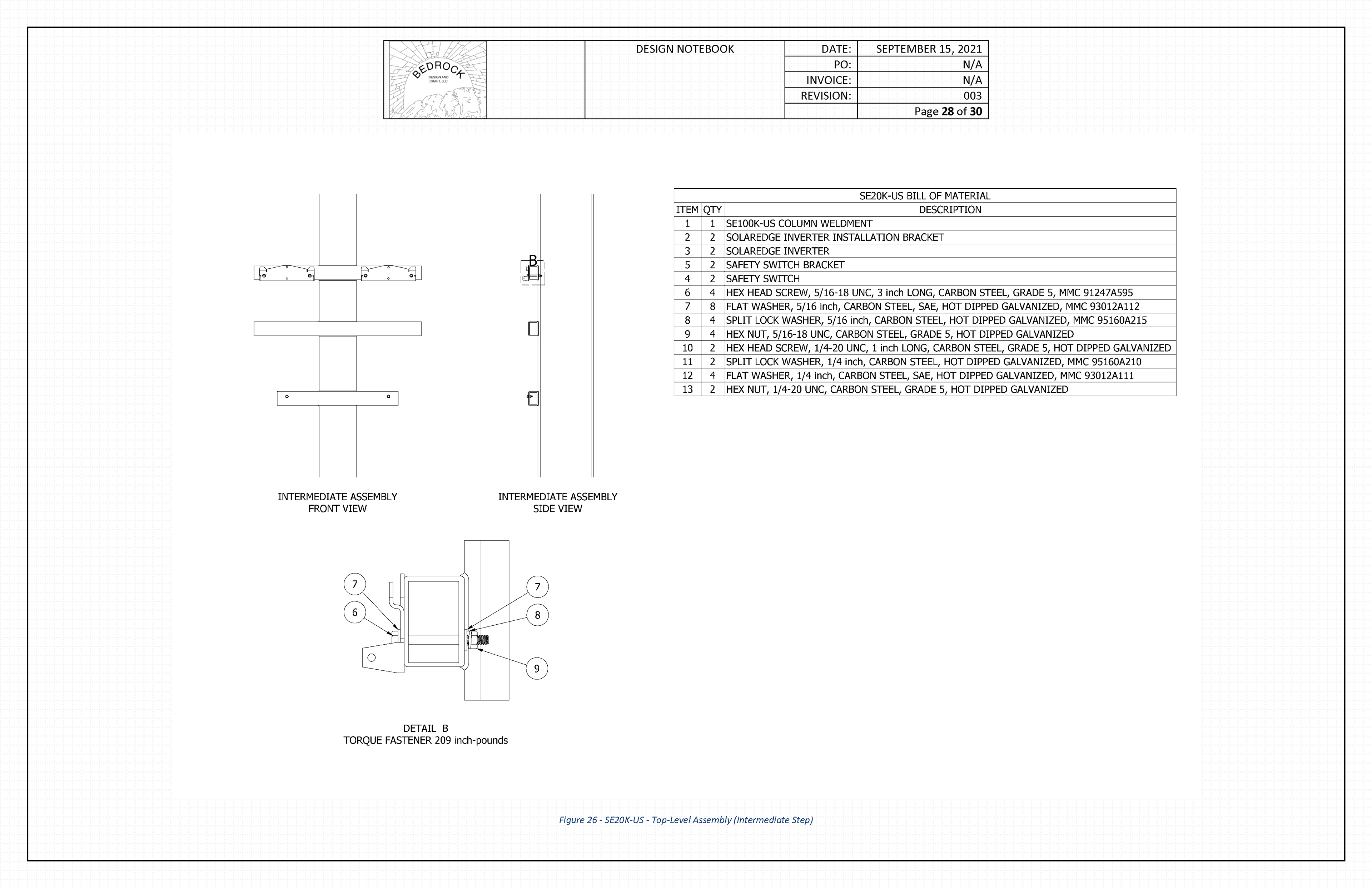

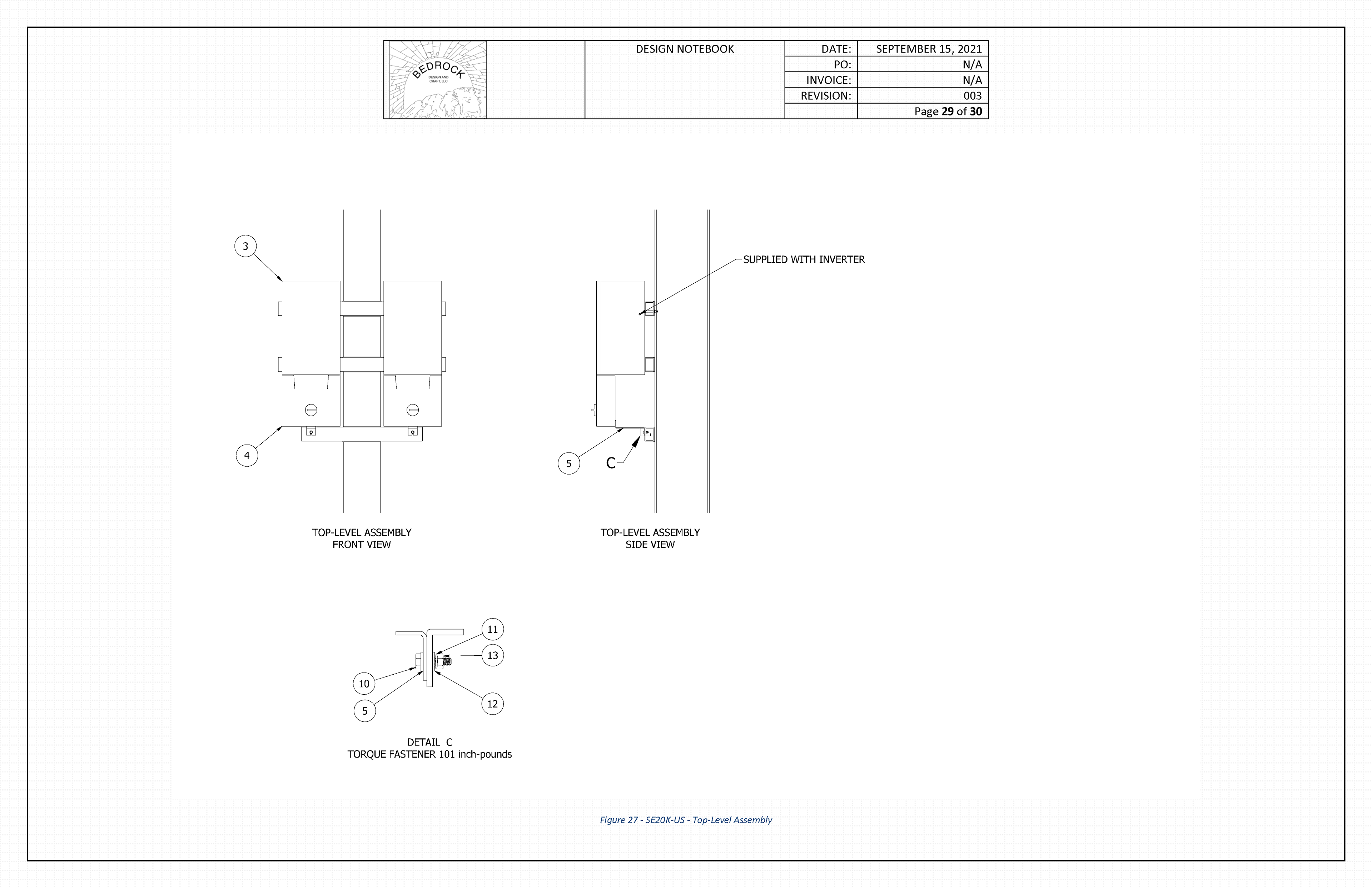

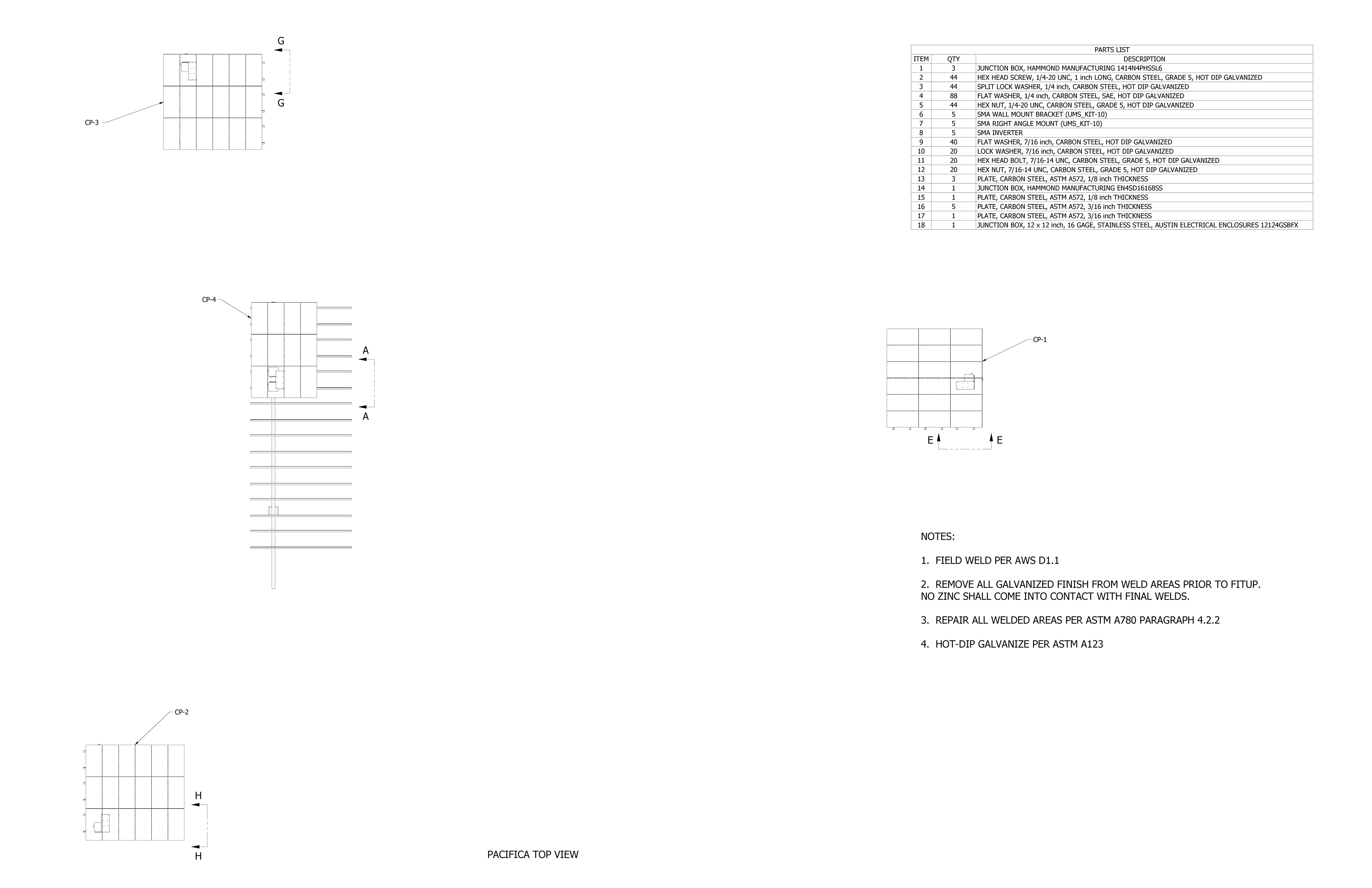

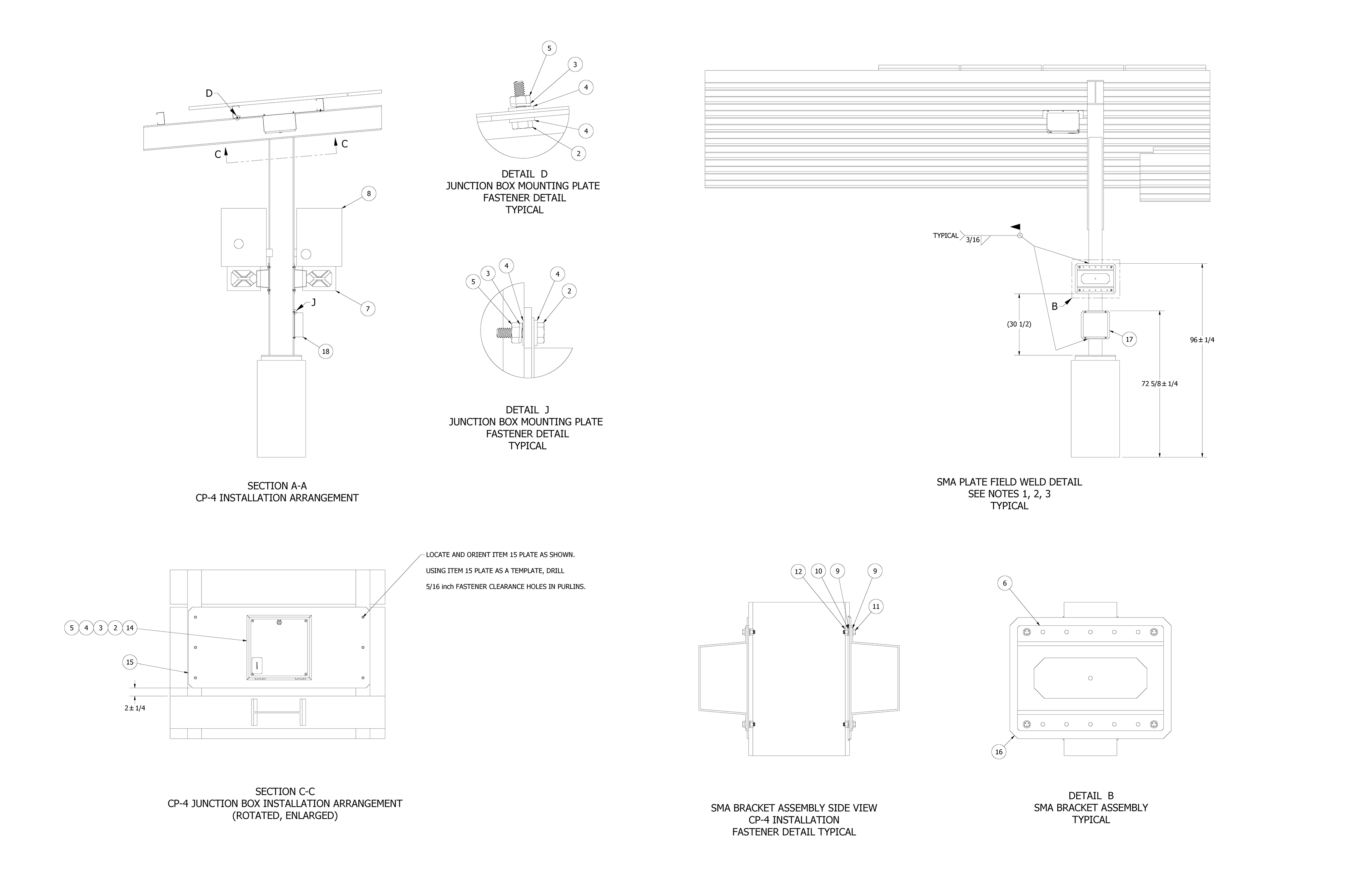

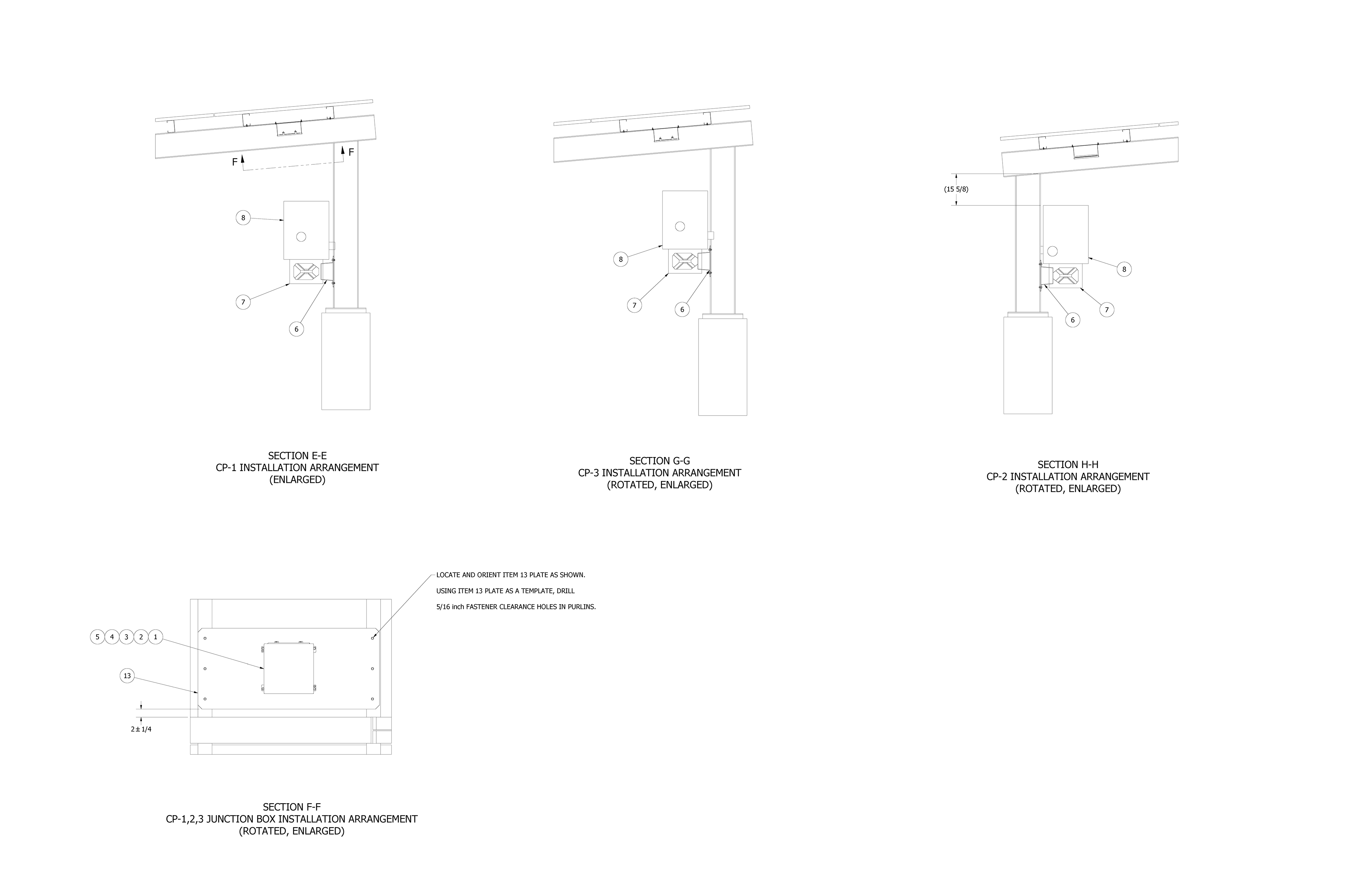

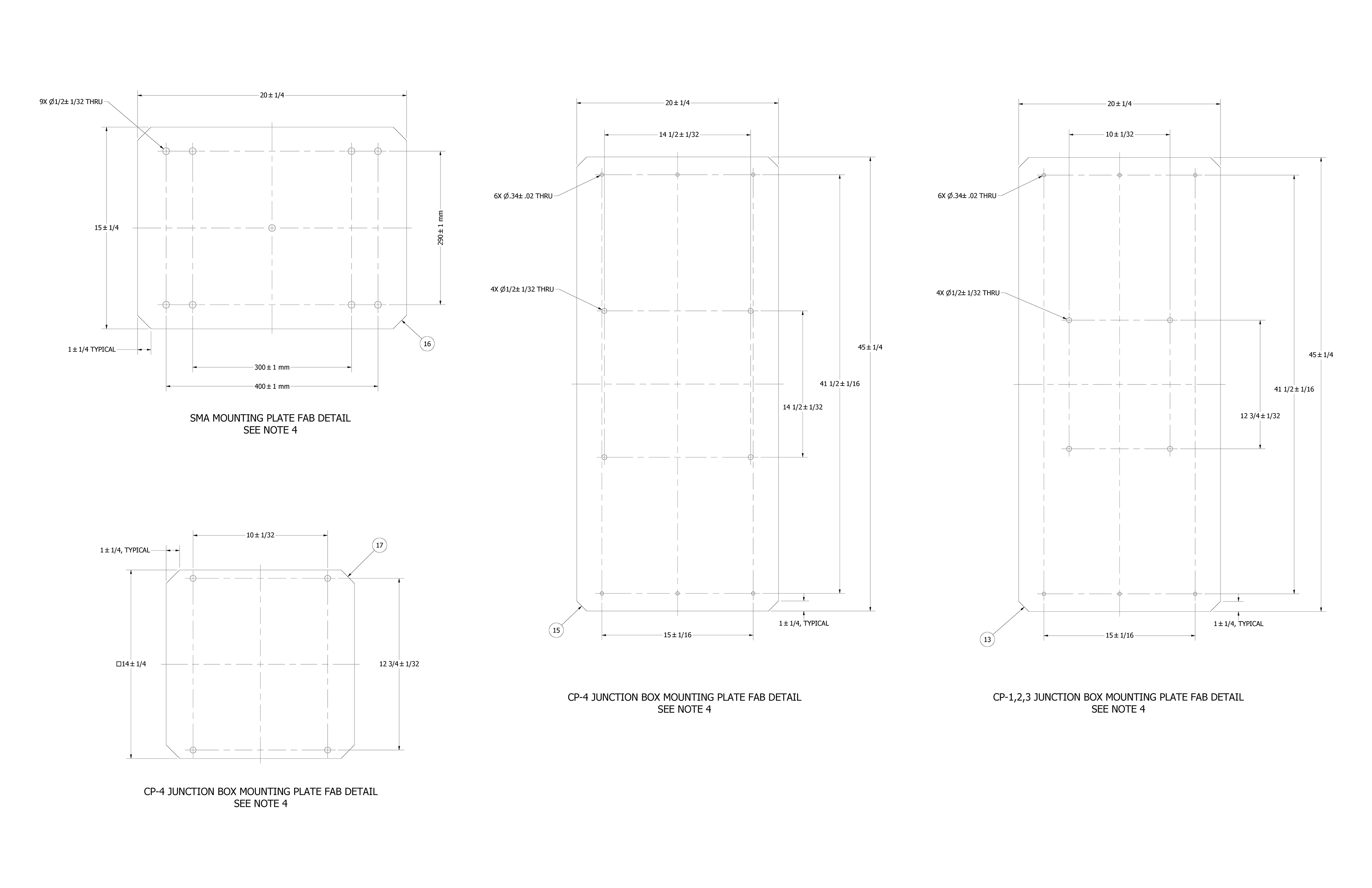

FIELD ASSEMBLY WELDMENT DRAWING

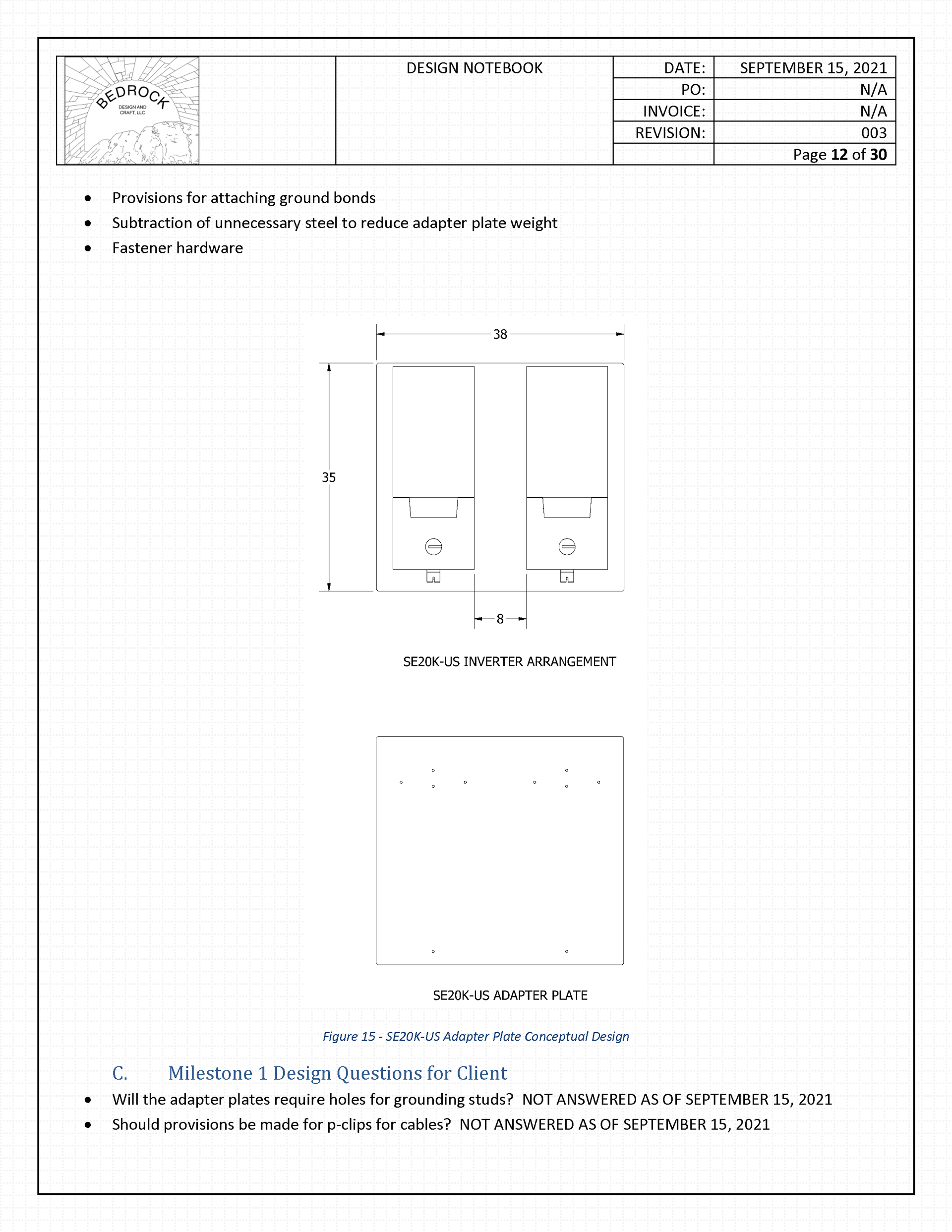

The project mechanical design was detailed to provide fabricators with the mechanical definition of individual parts and field welders with the orientation, weld size, and fitup of all the parts. All of the design elements (bill of material, fabrication details, weldment assemblies, item bubbles) were pulled together into a single drawing file with multiple sheets. This format is easily reviewed by all stakeholders and ensures everyone involved has a holistic view of the project.

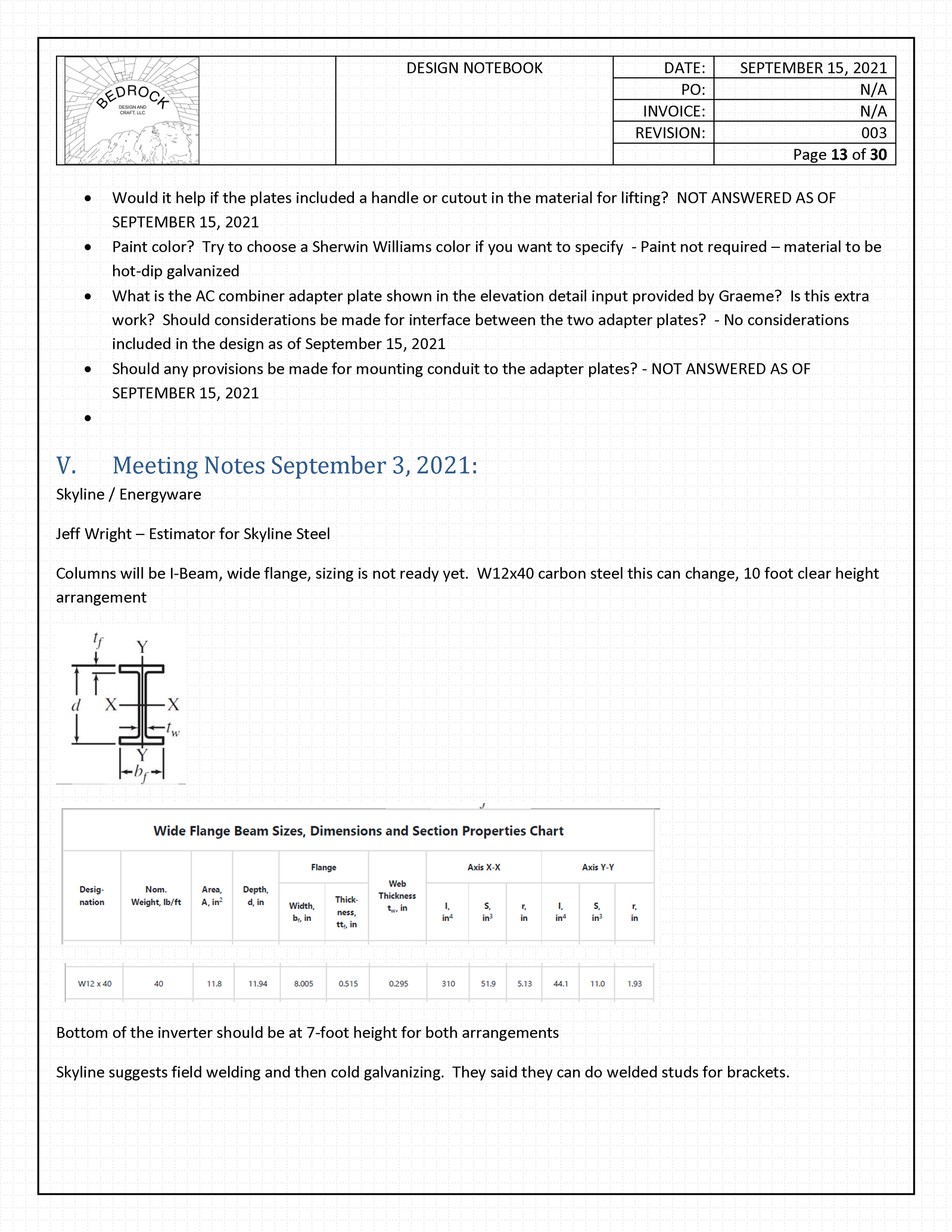

FABRICATION AND DELIVERY

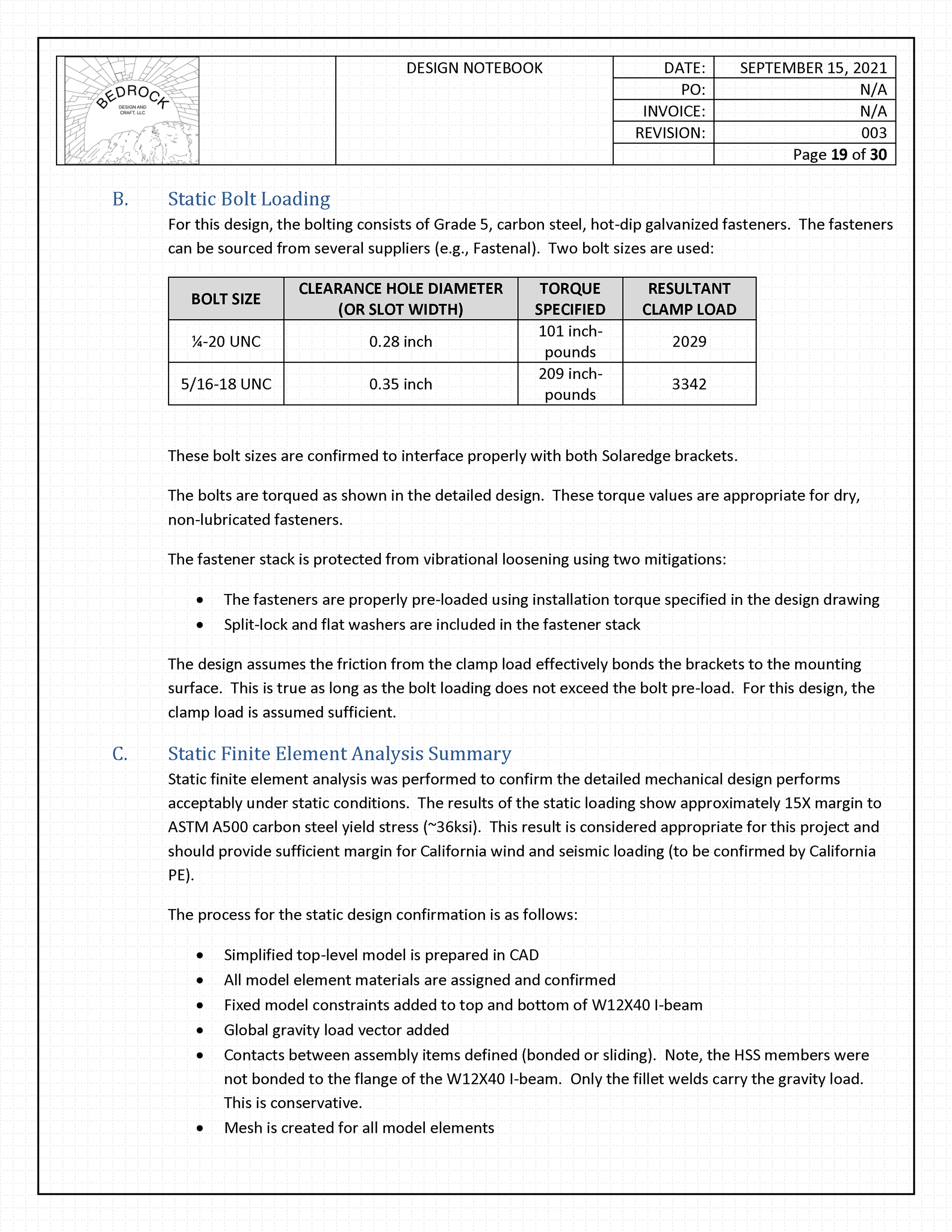

Blue Ryzon teamed up with local trades personnel to erect the structural carport framing to stamped plans. The inverter and junction box mounting plates were then welded and fastened to the steel framing. The solar system was assembled to the new infrastructure and vehicles are parking and charging today.