ABOUT THE CLIENT

Project MFG's overall mission is to evangelize trades as an occupation and work to restore America's technical excellence in manufacturing.

Project MFG has chosen Bedrock Design and Craft, LLC to provide weldment design services. Each project is presented to students and trade professionals in competitions sponsored by Project MFG. The designs are welded by everyone participating and the final weldments are judged at the end of the competition. Participants can earn prizes and notoriety for themselves and their school/trade program.

INTRODUCTION

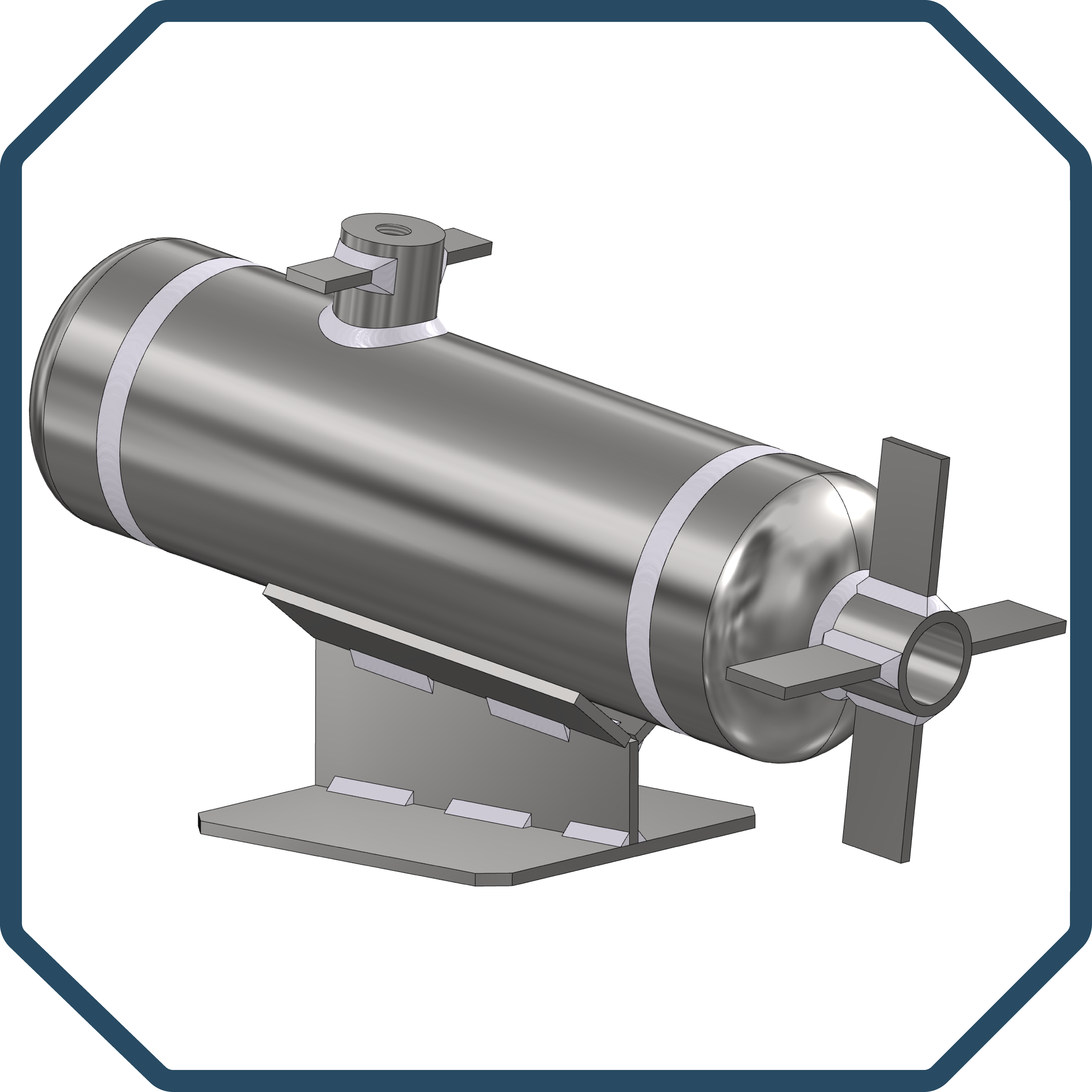

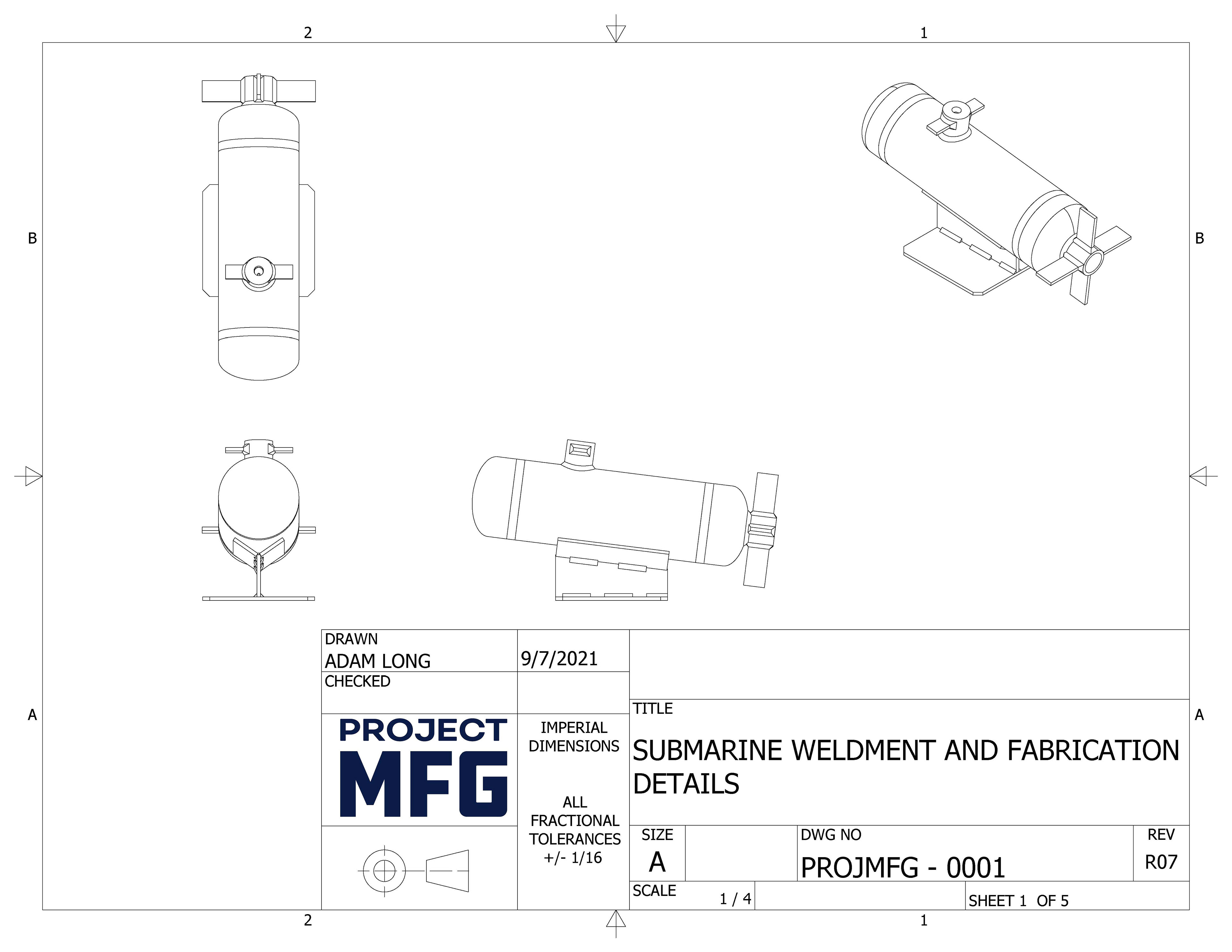

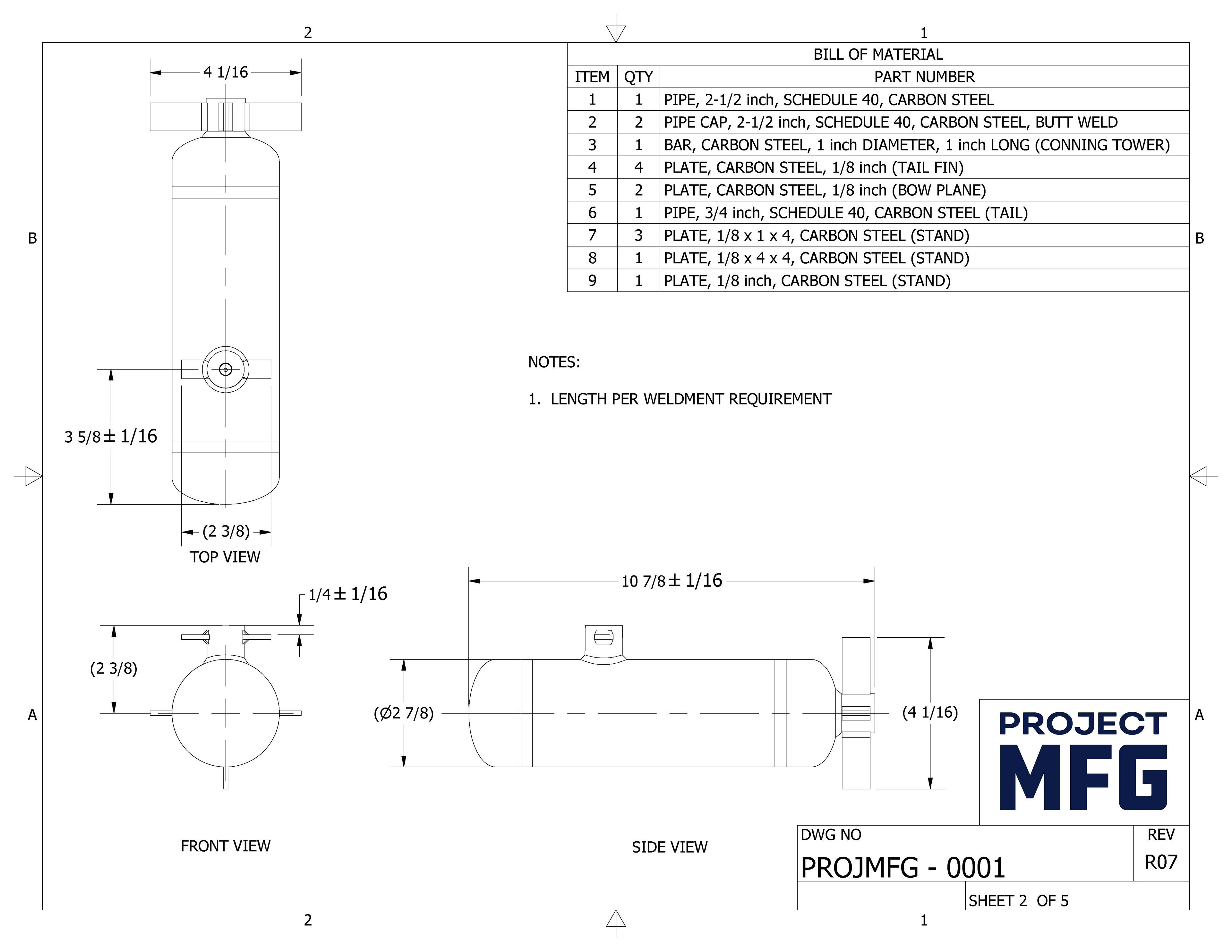

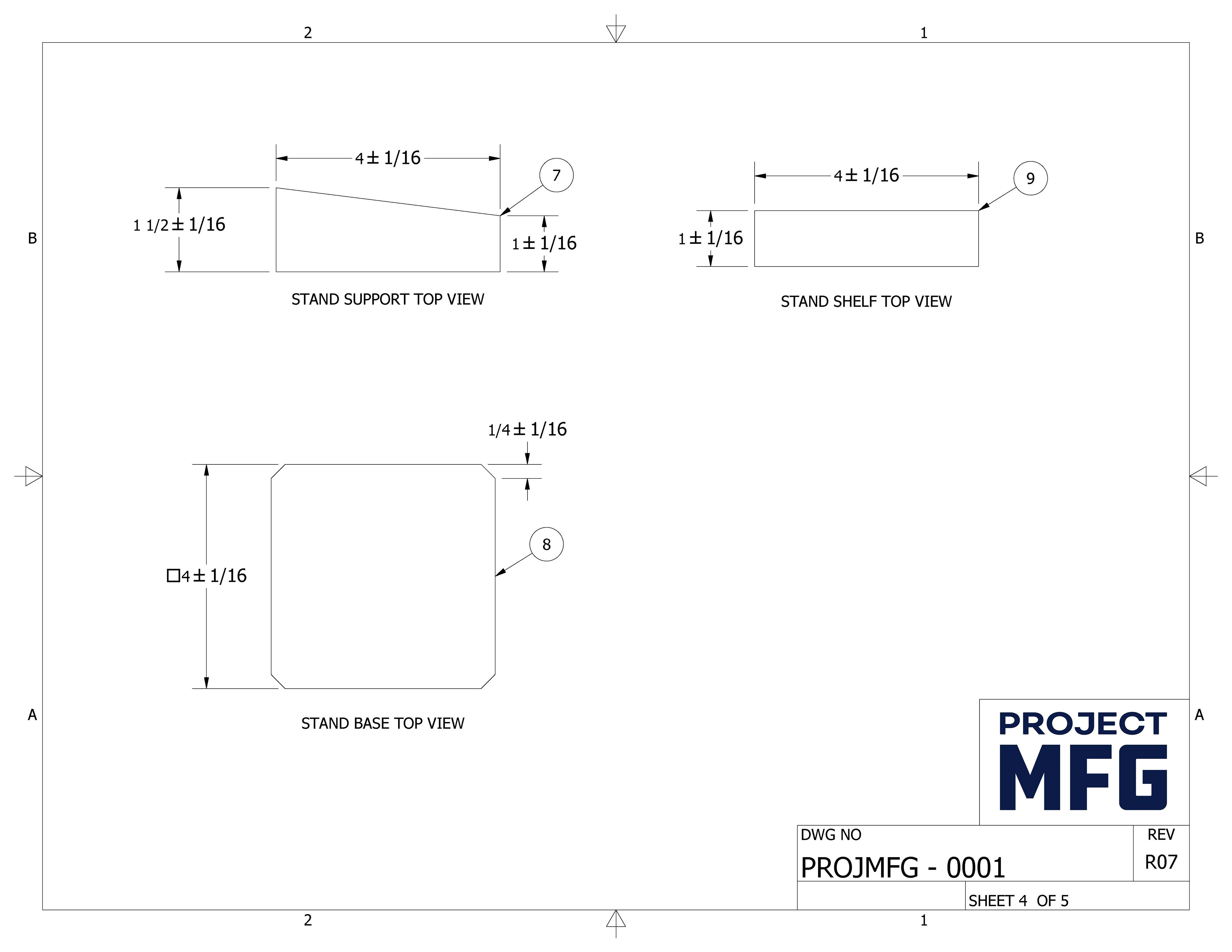

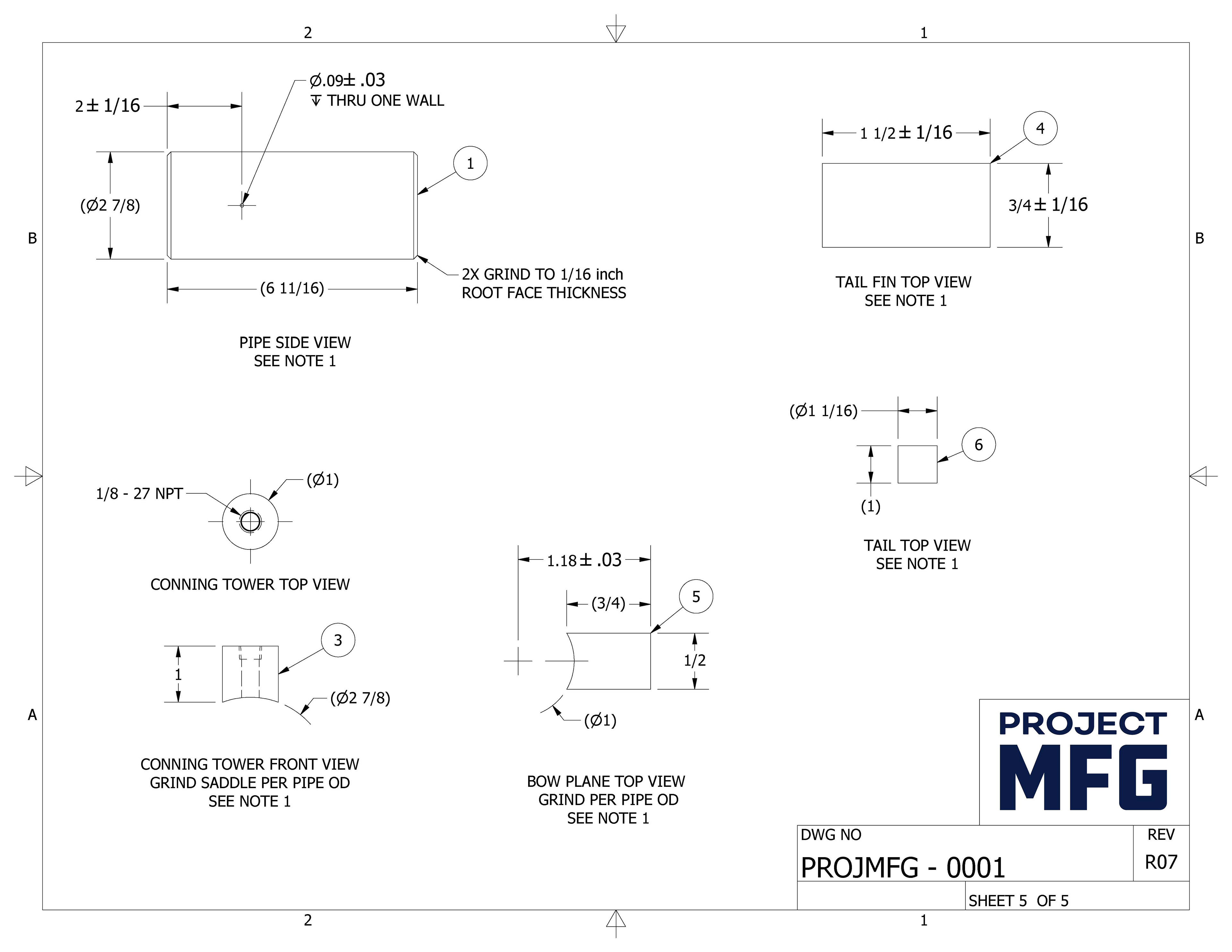

Project MFG worked with contacts in the US Navy to conceptualize a weldment design that presented a challenge to competitors and also tied the design to the organization sponsoring the competition. The result was scaled and simplified versions of submarine shapes commonly found in the US Navy fleet. For Bedrock, the objective was to evoke the submarine shape while simultaneously providing a weldment design that uses very common skills required in the welding industry to produce. Commercial-off-the-shelf parts and custom-designed and fabricated parts were combined together in a single weldment.

PROJECT SCOPE

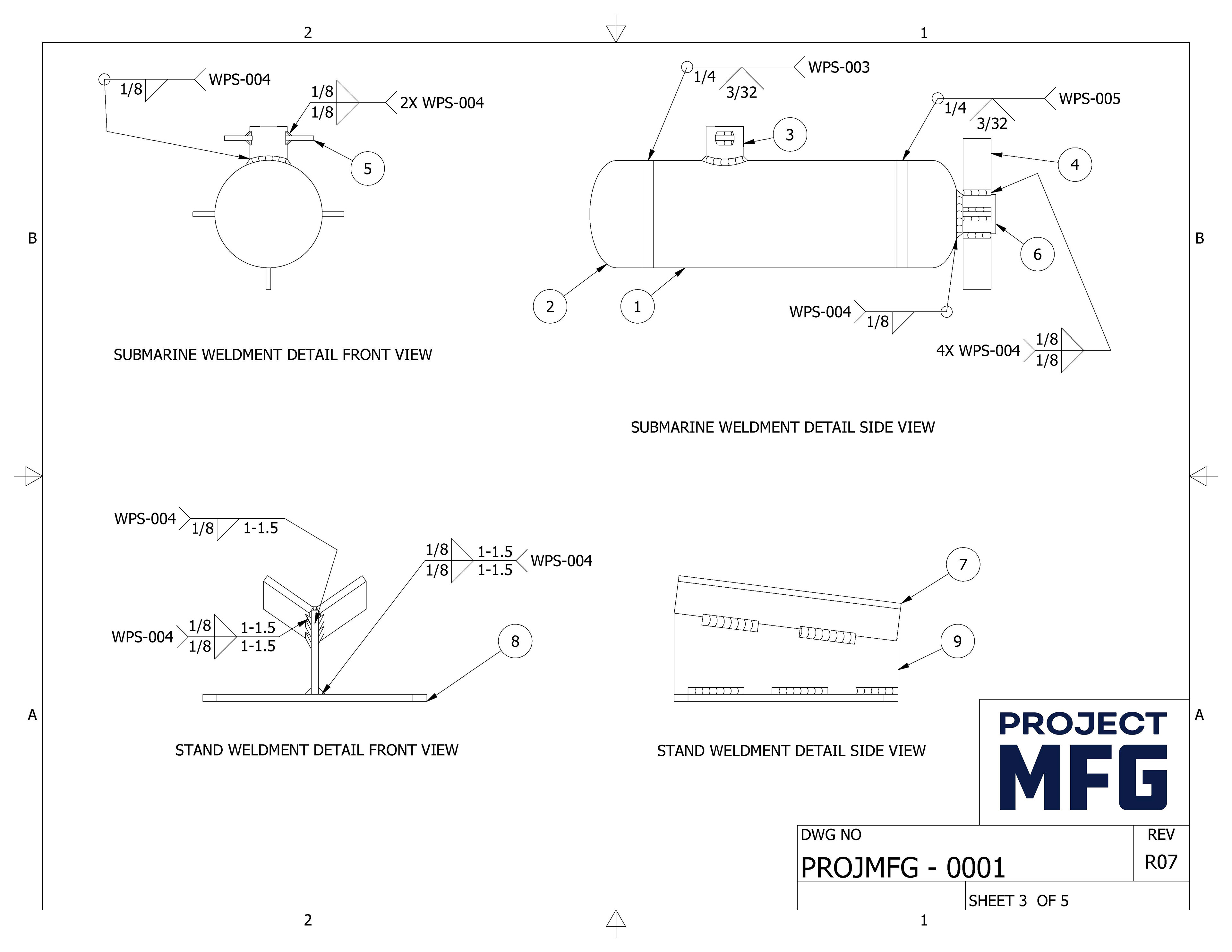

This project required conceptual design, solid modeling, top-level assembly drawing, and fabrication drawing detailing. Weld procedure specifications were written by Bedrock and validated by industry experts.

DESIGN PROCESS

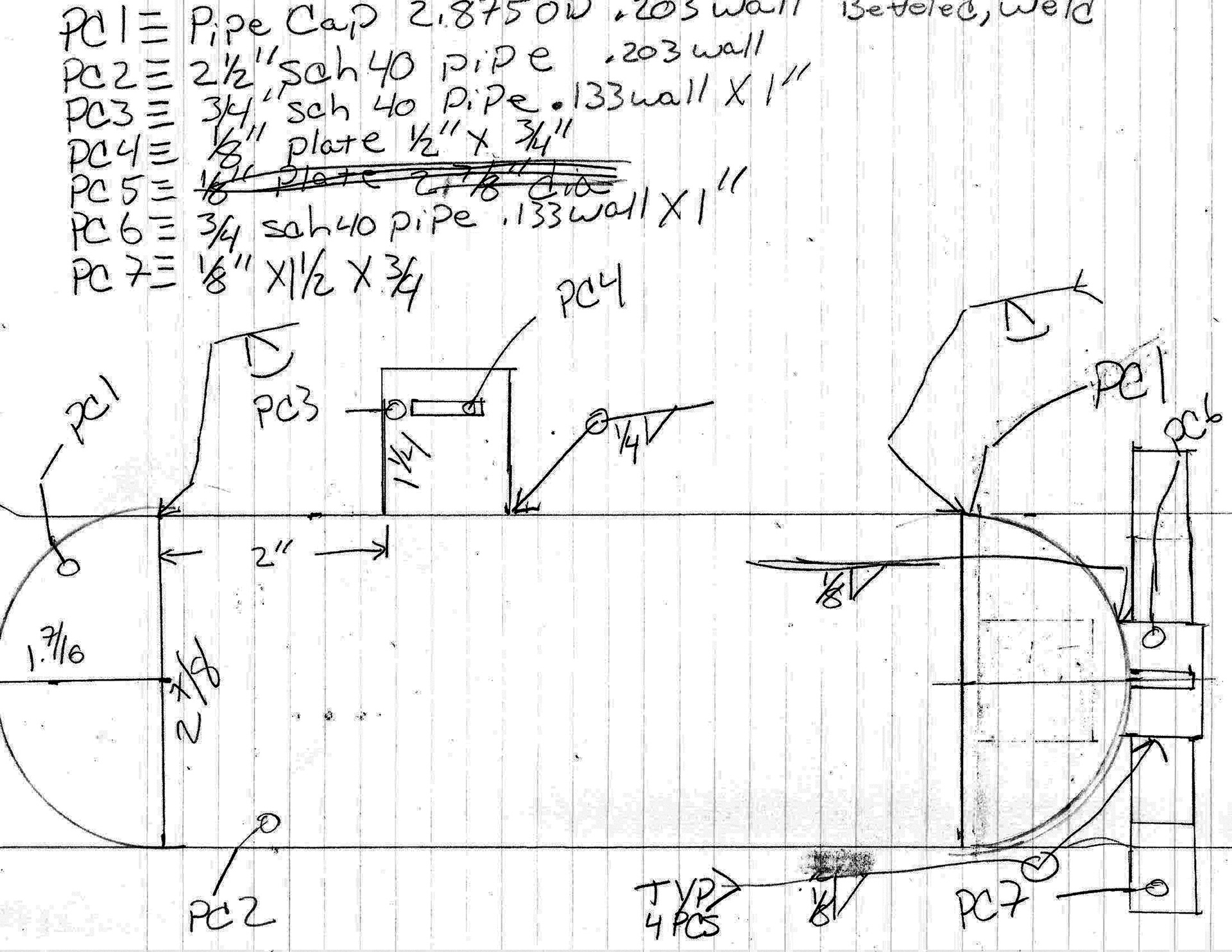

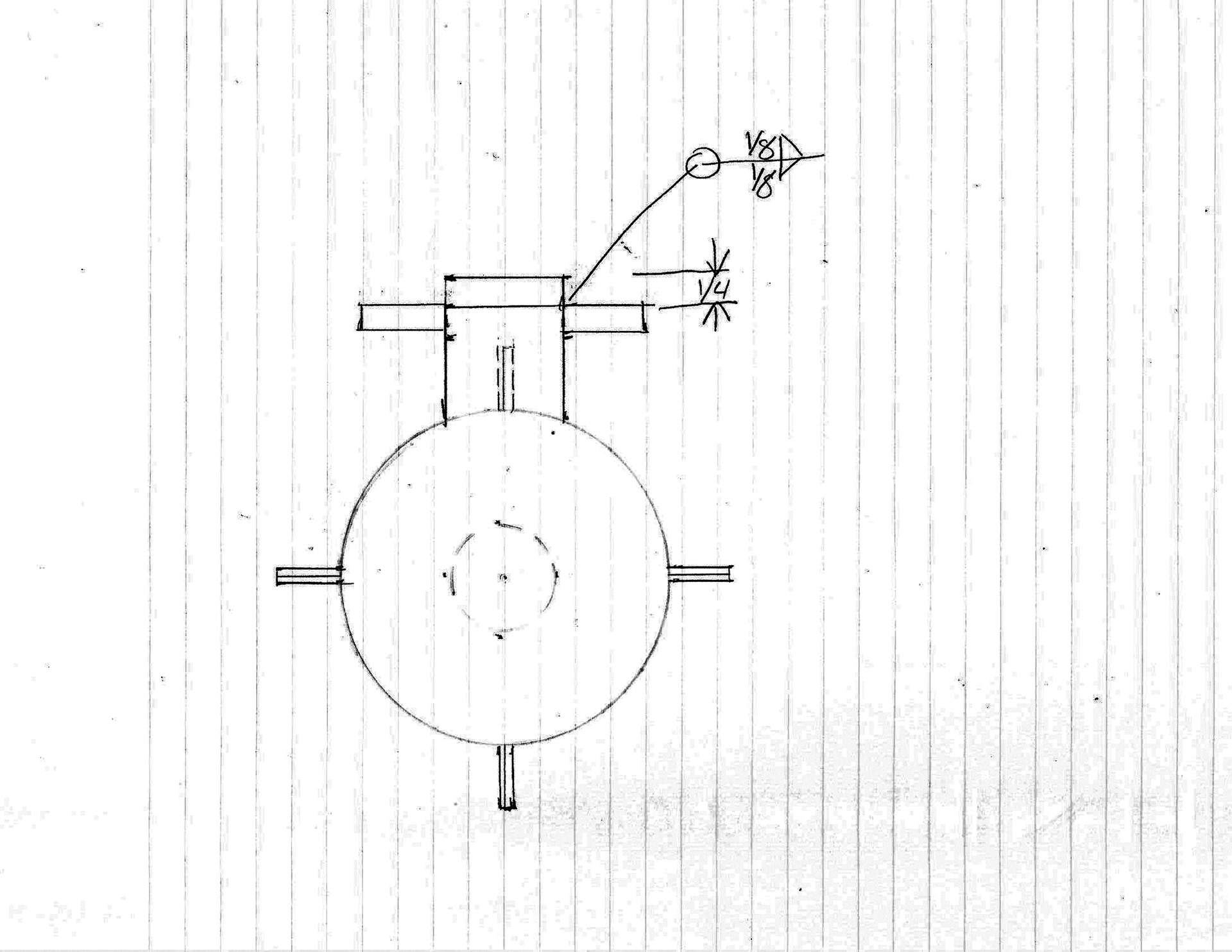

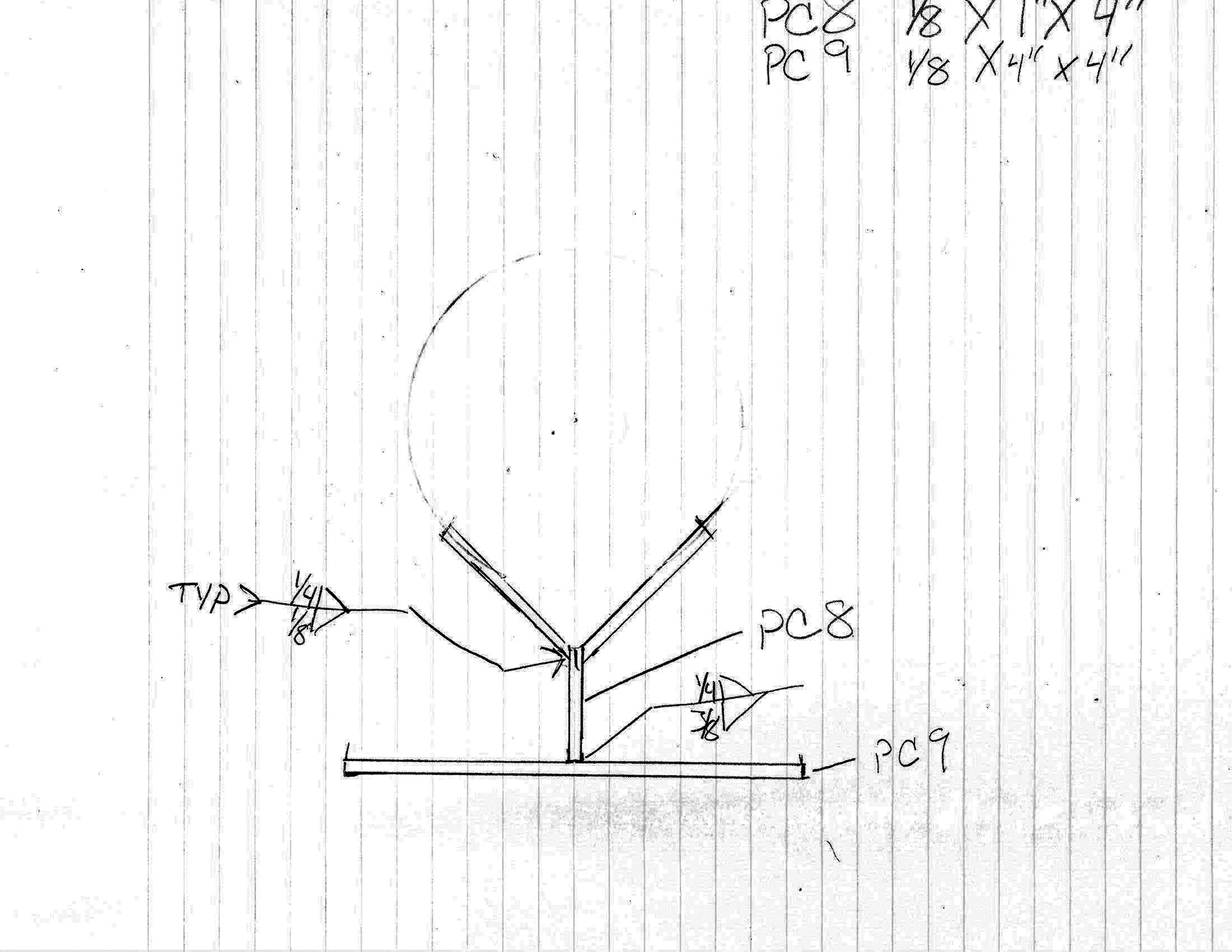

The submarine weldment concept was presented to Bedrock as a pencil drawing on lined paper.

INPUT SKETCH 1

INPUT SKETCH 2

INPUT SKETCH 3

The first objective was to formalize the conceptual designs in CAD using Autodesk Inventor. Then, a bill of materials for each piece of the assembly and detail drawings were defined for procurement of piece parts and as a book of plans to define the weldments. Next, weld procedure specifications (WPS) were written to define the welding power supply settings to be used to fabricate the weldments.

The weldment design drawings were reviewed by competition organizers and validated by industry professionals. Refinements were added over time in response to competitor feedback.

FABRICATION AND DELIVERY

Project MFG sourced weldment parts from US-based machine shops. The organizers procured all of the parts required for multiple competions in kit form and they were delivered to multiple competition sites. It is extremely advantageous to take the time and formalize drawings because the weldment designs have been used over and over again to buy parts and provide material for many competitions. Bedrock Design and Craft, LLC is providing long-term support to the organizers by answering supply chain questions and providing design optimizations.

Check out pictures from example competitions:

SSBM WELDMENT