INTRODUCTION

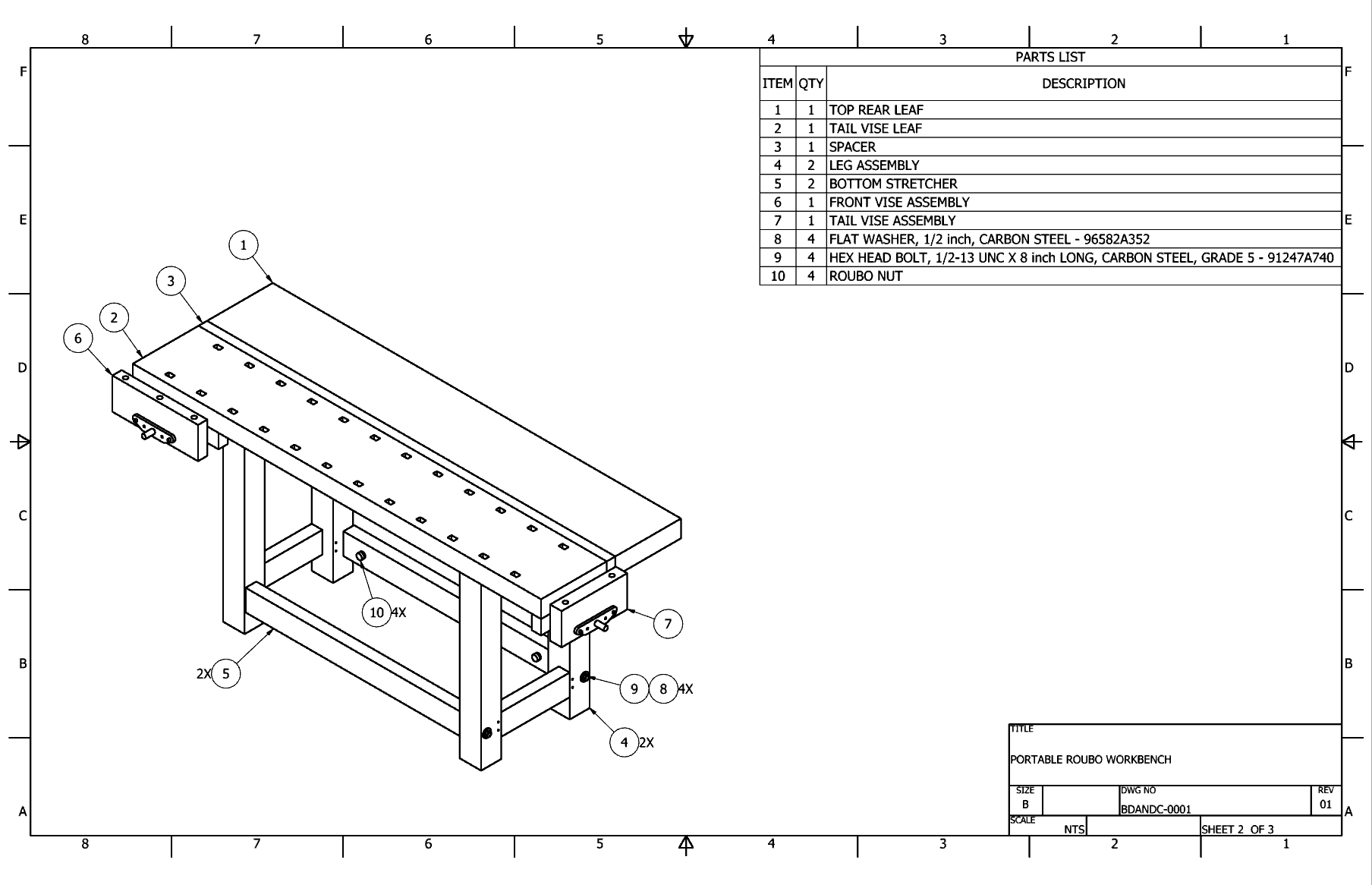

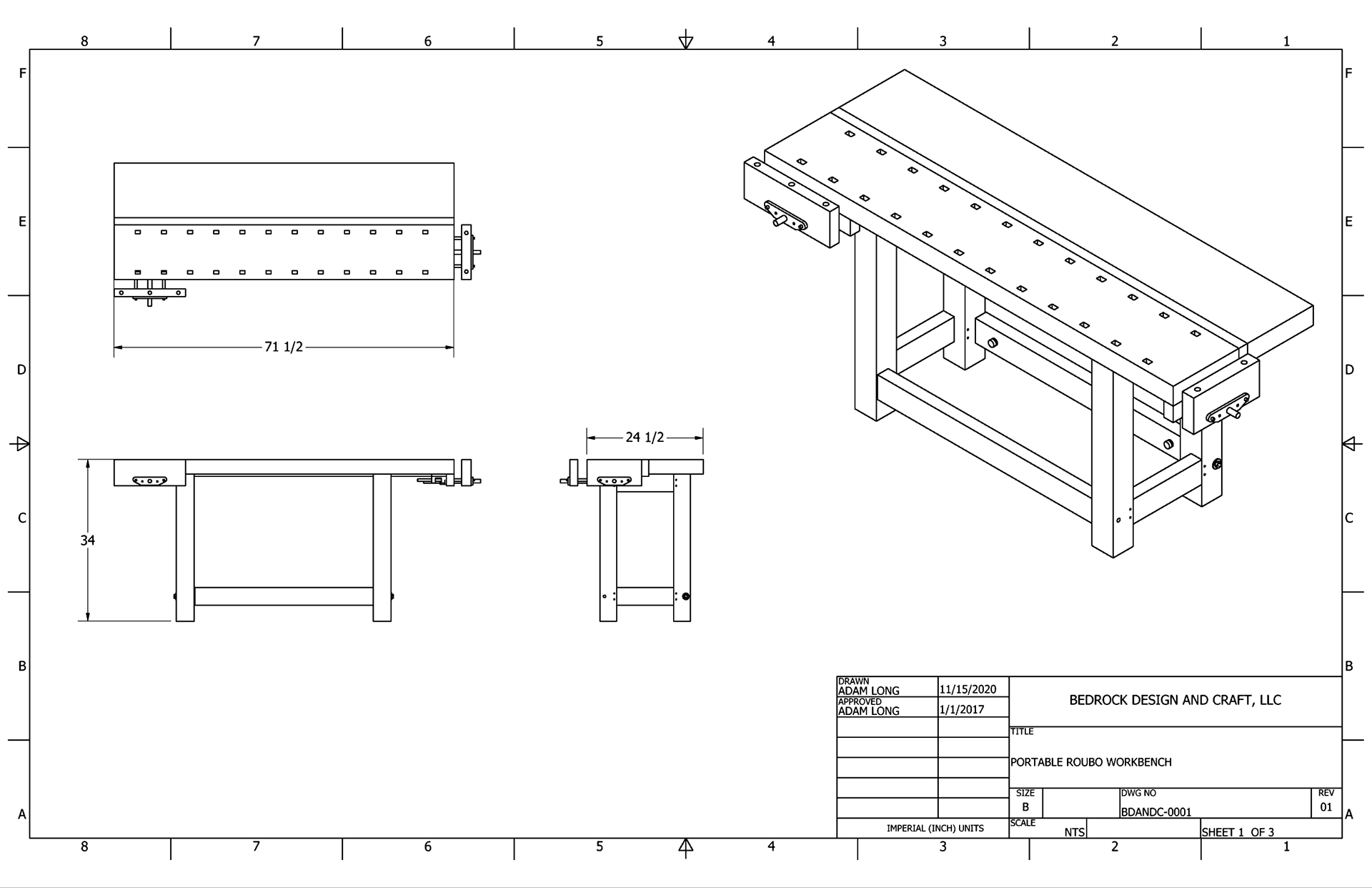

This project was intended to build a strong, stable, solid workbench suitable for building furniture parts. The workbench had to be stiff and heavy enough to stay in one place during planing, milling, drilling, and routing operations. The workbench also had to be portable to break down and re-assemble at different job sites.

PROJECT SCOPE

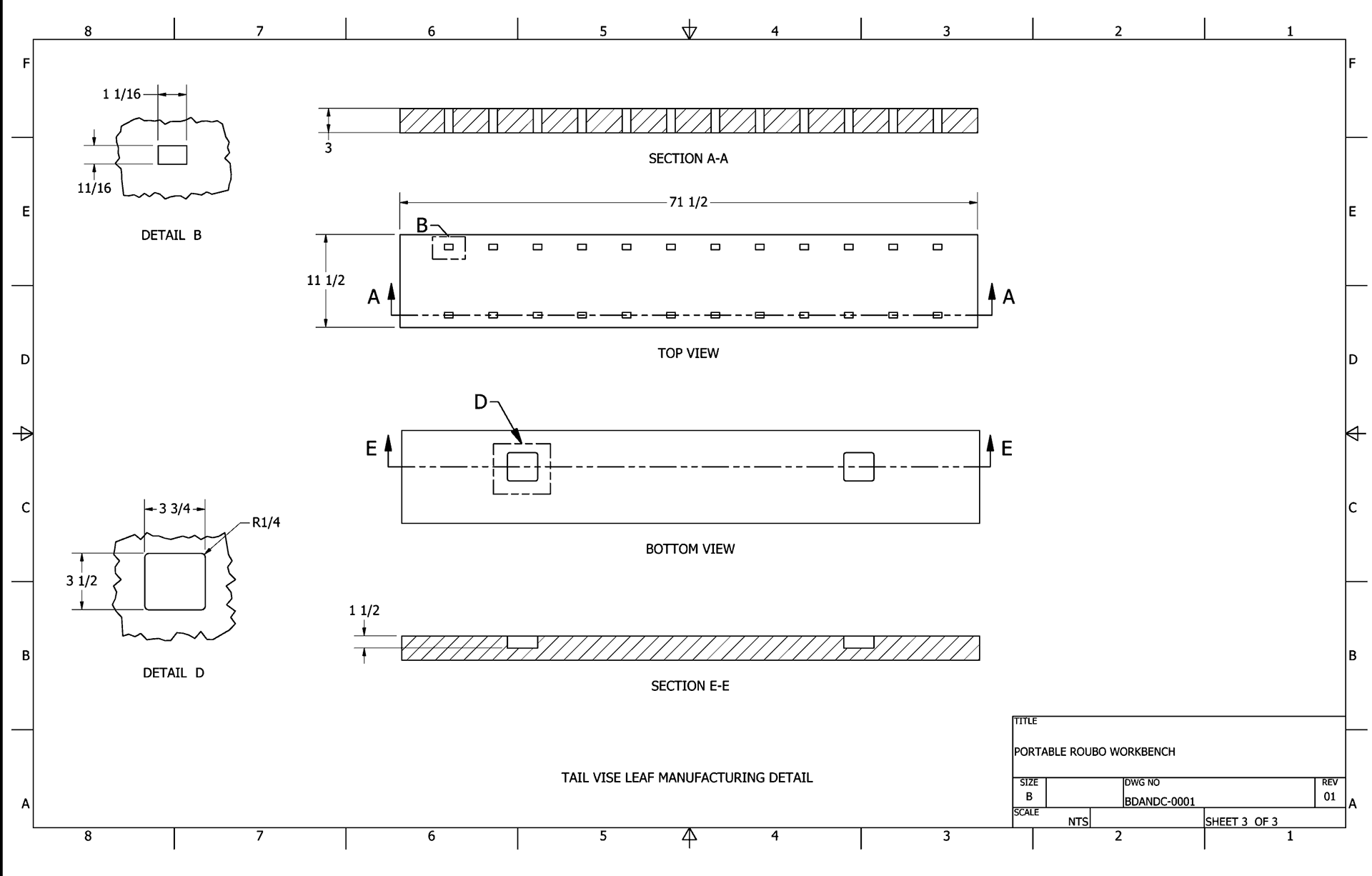

The scope of the project required a complete set of workbench top-level assembly and detail drawings.

The state-of-the-art for workbench designs was assessed by reviewing competitor’s designs already on the market.

The project was complicated by the need to design and build a portable workbench that could be trucked to job sites.

Using Autodesk Inventor solid modeling, the final workbench design incorporated many aspects of existing commercial workbench designs. Both front and tail vises are included. White oak is the material of construction to ensure strength, stability, and sufficient weight. It is possible to drill 3/4 inch holes in the top leaves to provide mounting points for hold-down fixtures. Slots were milled in the front leaf to permit installation of stops to enable pinching long stock between the tail vise and the stop.

The portability requirement meant knock-down fasteners were required to be sourced to provide sufficient strength during use while simultaneously supporting the ability to break the workbench down into component parts.

To satisfy this requirement, eight inch long, carbon steel, 1/2-13 UNC fasteners and roubo hex nuts, in combination with both dry and glued blind mortise and tenon joints, permit breaking a >200 pound workbench into seven major component parts that can be lifted and moved by a single person for transport in a standard pickup truck.

To satisfy this requirement, eight inch long, carbon steel, 1/2-13 UNC fasteners and roubo hex nuts, in combination with both dry and glued blind mortise and tenon joints, permit breaking a >200 pound workbench into seven major component parts that can be lifted and moved by a single person for transport in a standard pickup truck.

FABRICATION AND DELIVERY

The detailed design drawings defined the requirements for each individual part. The parts were milled and shaped into the necessary geometry to form the final assembly.

The tail vise leaf and the front leaf were glued together using double biscuits across the 3-inch width of each piece of white oak.The legs were glued together using blind mortises, shaped tenons, and then pinned using walnut pegs into a manageable sub-assembly.

WORKBENCH LEAF GLUE-UP

LEG SUB-ASSEMBLY BEFORE GLUING

GLUED AND PINNED LEG SUB-ASSEMBLY

CONCLUSION

The workbench was assembled and used to create over ten pieces of heirloom furniture. The assembly was moved and re-assembled over six times without issue.

FACE VISE AND CENTER STOP